I recently had a discussion with a surveyor who could not understand why I have my TS and tribrachs cleaned and calibrated once a year. I was taught to do this back in the 80's before I was licensed. I check and adjust my own prism poles. But I am curious how often, if at all, members of this group have their TS and Tribrachs adjusted.

Sent from my iPhone using Tapatalk

I'm just a young buck, but I bitch and moan if the TS isn't sent in once a year. That quality has been both a friend and an enemy, take it for what its worth.

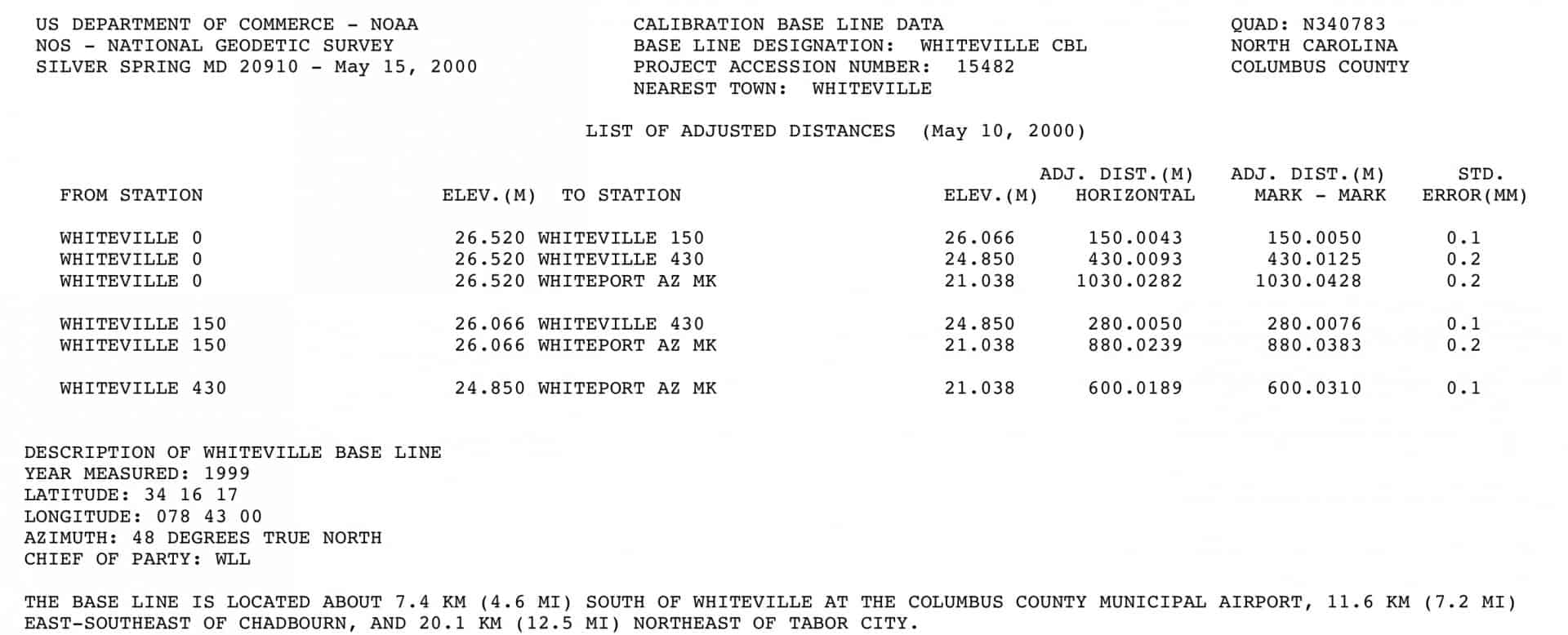

Better than that, adjust the tribrachs yourself and get to a calibration baseline.

Mark Mayer, post: 410444, member: 424 wrote: Better than that, adjust the tribrachs yourself and get to a calibration baseline.

Good suggestion. I have been considering adjusting my own tribrachs. I will probably invest in some calibration cylinders at some point. But the calibration baseline is too far from my office to be cost effective for the TS. TS calibration is about $200.

Sent from my iPhone using Tapatalk

BushAxe, post: 410440, member: 11897 wrote: I am curious how often, if at all, members of this group have their TS and Tribrachs adjusted.

Sent from my iPhone using Tapatalk

Total stations serviced once a year, baseline once a year and field calibration whenever I feel they aren't performing as I'd like. All other equipment including tribracks are checked probably 2 times a year all together, and individual pieces checked before accurate work and adjusted if needed

BushAxe, post: 410447, member: 11897 wrote: Good suggestion. I have been considering adjusting my own tribrachs. I will probably invest in some calibration cylinders at some point. But the calibration baseline is too far from my office to be cost effective for the TS. TS calibration is about $200.

Sent from my iPhone using Tapatalk

FWIW,

Just curious, is the Whiteville CBL unusable or is ~50 miles too far? BTW, did anyone comment to NGS on the new CBL policy? The comment period has already passed. Details are on the CBL page here: https://geodesy.noaa.gov/CBLINES/calibration.shtml

Cheers, DMM

I adjust my tribrachs myself, but I take my robot in for professional adjustment once a year (more often if necessary). I take it with me when I go to the TAPS conference in the spring. Troy Deaton is always there, and if you drop your instrument off with them on the first day, they will get it back to you by the time the conference ends. That way, you won't have any down time due to your instrument being in the shop.

I drop off the robot at least once a year for calibration. Same with Tri-brachs. I rather have the professionals adjust the robot.

C Billingsley, post: 410461, member: 1965 wrote: I adjust my tribrachs myself, but I take my robot in for professional adjustment once a year (more often if necessary). I take it with me when I go to the TAPS conference in the spring. Troy Deaton is always there, and if you drop your instrument off with them on the first day, they will get it back to you by the time the conference ends. That way, you won't have any down time due to your instrument being in the shop.

I met and spoke with Troy in Georgia, he is a really nice guy.

Being the son of a mechanical engineer I learned to adjust equipment over the years. They all are basically the same, so the skill works across different manufacturers (Trimble could be an exception). I took things apart, cleaned and fixed what I could. For my TS I bought a second "for parts only" machine and have it on hand to service the good one. I use known baselines and verify the DM periodically. Tribrachs get a check every 3 or 4 months. Tightening up the tripods is a must. Rods after every job (the jig is set up and just takes a few seconds to verify).

That being said - the TS goes into the dealer every 2 years for a look. Never hurts to get a second opinion.

We send our calibration TS away for a full independent calibration every 3 or 4 years.As soon as it comes back it goes on a local baseline we have which replicates the pillar spacing on the calibration line. Set up 8 tripods - read with calibration instrument; then each of the other instruments goes on in turn so we have a complete set of data for each to compare with the calibration unit. (overall length is about 900 metres).

Graph the results and you can then determine the scale and constant corrections to apply to each. The calibration instrument is kept for "special" jobs only, so it gets very well looked after.

Tribrachs - checked yearly and before/after any high accuracy jobs. You can adjust them well enough yourself to within half a millimetre (we use a template on top of the tripod so that each time you turn them through 120 degrees they sit back in exactly the same location on the head). If anything closer is needed we would adopt a subtraction measurement technique using a backset station for the line to be measured. That way you eliminate any centring errors on the distance (but not necessarily on the angle).

As already mentioned CHECK THE TRIPOD LEGS.

And don't forget to compare all the prisms and holders with each other. It's a good way of filling in those spare days.

For vertical precision, total station should be field calibrated every 20-40F of temperature change depending on manufacture.

My thoughts are that taking a delicate (plastic) instrument apart needlessly is probably not good practice.

They should probably be sent to a shop and adjusted when the check measurements indicate that the errors exceed your requirements.

Most TS's have a collimation routine that will inform you when the errors exceed the instruments ability to compensate for errors.

Same thing with a level....nobody is touching my level until I have determined that it needs adjustment.

Most instruments have internal batteries that need to be replaced from time to time (sometimes as frequent as every 2 years)...that's usually a good time to have it cleaned/adjusted, firmware re-loaded/upgraded.

If your instrument is getting knocked out of adjustment in 12 months of use...it's getting banged around somewhere between the trip to the coffee shop and the office at the end of the day. I'd also look at where it is being stored in transit (near the tailgate is a horrible place).

Truthfully, I often wonder what the heck they do when someone sends in a perfectly good total station....perform some checks....wipe a few parts with a Q-Tip, slap a sticker on the case and send out the bill to make some feel better?

Tech to shop manager...."everything looked good, what should I put on the invoice?"

Shop Manager to Tech..."Throw some of those 99 cent O-rings on there and I'll handle the invoice."

Based on my experience, it depends on the qualifications of the shop you send it to. The training, specialized jigs and test equipment, and software aren't cheap and not every dealer makes the investment. I know that if I send an S6, for instance, to the local Trimble shop they're going to hook it up to the PC and run all the computer diagnostics.

Someone who doesn't have that training and equipment or who doesn't support your brand of instrument can't do much - if anything - more than you could do yourself.