I admit that I should have snapped to this years ago. I'll be sure to add this one to my New Year's Resolutions, but somehow it had never occurred to me to actually look at the catalogs of manufacturers of steel pipe, both galvanized and black iron. Had I done that, I would have spared myself the recent realization that those very corroded 5/8-inch i.d. iron pipes I was finding were actually very corroded 3/4-inch iron pipes. Apparently, 5/8-inch i.d. iron pipe was never manufactured for plumbing use.

At this point, I'm thinking that the best clue for identifying the sizes of old Schedule 40 steel pipes is probably the outside diameter since corrosion will thin the walls and reduce the outside diameter, but if the outside diameter is still larger than 1 inch, it is quite unlikely to be 1/2-inch pipe and must be 3/4-inch.

Now you are figuring it out grasshopper! I was very surprised to find coat hanger sized iron rods that fit very well. They were set with a transit and tape about 100 years ago and fit better than most of the stuff you find today. I am not sure what size they were when they were set. It felt good to set some new iron that was referenced to them. I have to actually give credit to my field crew for finding them. I was kinda impressed. There was a bunch of metal built up over the years in the area. Had to use a tape to find them imagine that. If only they had an old transit to help.

Central Texas has very few highly corrosive soils. The commonest soil being an alkaline type from limestone and our low annual rainfall means ungalvanized pipes and rods last very well. The main exceptions are in soils with high moisture content. These "5/8-inch" pipes may be partly the result of some deformation of the top of a 3/4-inch pipe from driving and partly just the hole in the pipe being lined with soil cemented by corrosion of the pipe.

The wikipedia entry on pipe sizes includes the following:

[INDENT=1]"...Pipe sizes can be confusing because the terminology may relate to historical dimensions. For example, a half-inch iron pipe does not have any dimension that is a half inch. Initially, a half inch pipe did have an inner diameter of 0.5 inches (13 mm)ÛÓbut it also had thick walls. As technology improved, thinner walls became possible, but the outside diameter stayed the same so it could mate with existing older pipe, increasing the inner diameter beyond half an inch. The history of copper pipe is similar...."[/INDENT]

Given that might it be possible to identify the age of a pipe by the thickness of the pipe walls?

Mark Mayer, post: 347194, member: 424 wrote: Given that might it be possible to identify the age of a pipe by the thickness of the pipe walls?

Interesting question. I had thought that Schedule 40 pipe used in plumbing applications had definite wall dimensions, but I'll have to check. There are differences in the welding techniques used in making iron pipe. Early 20th century wrought iron pipe was presumably made by a different process than modern electro-welded pipe is. Then there are unusual vintage pipes that were really boiler tubes.

Having lived near a steel mill, I've encountered so many different sizes of pipe set for monuments.

Many time I've thought I had found a pipe and it was actually a solid piece as much as 4in thick with a cup on the end.

These pipe come in increments of 1/16th inch and some are specialty pipe of like 2 5/16in and such.

In the oil & gas industry is used such a variety of pipe sizes, you really have to measure the pipe with a micrometer inside and outside to know for sure.

But in the range of 1/2-inch to 1-inch, aside from Schedule 40 and Schedule 80 plumbing pipe, what sort of pipe would one see aside from some thin-wall tubing?

Most of the 5/8in pipe that several local surveyors set before 1975 was made from cold steel as most of the pipe that came from US Steel Plant in Lone Star, Texas. I've seen it in thin wall and thick wall.

Cold steel I've found locally for monuments were 3/8in rod, 3/8in pipe, 1/2in rod, 1/2in pipe, 5/8in pipe, 3/8in strap, 1/2in strap, 3/4in strap (strap being 1/8in or 1/4 in) and 1/4in, 3/8in and 1/2in square rods.

Best monuments I've found were 1/2in t-rods. I've found them set in rockpiles and in roadways at Headright corners. Never found any in a stockpile. They are the ideal monument. Long lasting and will make a pin finder scream.

Most of the cold steel stock has depleted. Every once in a while a stack is discovered.

My mentor's father was a plumber. He kept three sizes of pipe. 3/8in thick wall, 5/8in thick wall and 3/4in normal wall.

We never used pipe for monuments, 3/8in cold steel rods for most monuments and small gauge rail for Headright monuments.

I once had a sample of all the various monuments that were used. Some @$$ho passed thru a few years ago and absconded with them. They were the perfect thing to teach the hands about describing what they had found.

I've always had the theory that you report what you see and measure. So if I find a 5/8" i.d. pipe with existing corrosion, I should report it that way. The size it was when it was originally manufactured is important, and if you can figure out that it is most likely the same original schedule 40 pipe, that is great as well. But, as a surveyor, my dimensions on the pipe would be what my tape measure reports. (If I couldn't measure the i.d., I might report it to be a x/y" o.d. pipe)

I set some new 5/8" inside diameter iron pipe back in the early 1990's. It was a long piece of scrap that I had picked up somewhere and cut up, but it was definitely 5/8" and not 1/2" or 3/4". Like most surveyors, I always have my eye open for scrap monuments, especially to use for reference ties since ID caps are not required here for those.

I have measured 5/8" inside dimensions on pipes that otherwise appeared to be larger than 1/2-inch Schedule 40 steel pipe and smaller than 3/4-inch, but I have yet to find any mention of a manufacturer actually making 5/8-inch steel pipe.

Well, maybe someone was making 5/8-inch iron pipe at one time. That would be the simplest explanation for what I've found in the past. My moment of doubt came from failing to find a 5/8-inch steel pipe in a manufacturer's catalogue, either present or early 20th century.

I think that better practice is to attempt to identify the size of the thing as set and, if necessary, mention that it is a "highly corroded 1/2-inch iron rod" or something to indicate it's present condition. The original size is what is more likely to connect to the record.

I've always wondered why you guys don't appear to have a firm industry standard on what type of monument to set. Two-inch iron pipe for boundaries, one-inch iron pipe for inside lot corners, for instance. You guys don't really just set whatever inconsistent el-cheapo miscellaneous iron scrap you happen to have laying around at the time, do you?

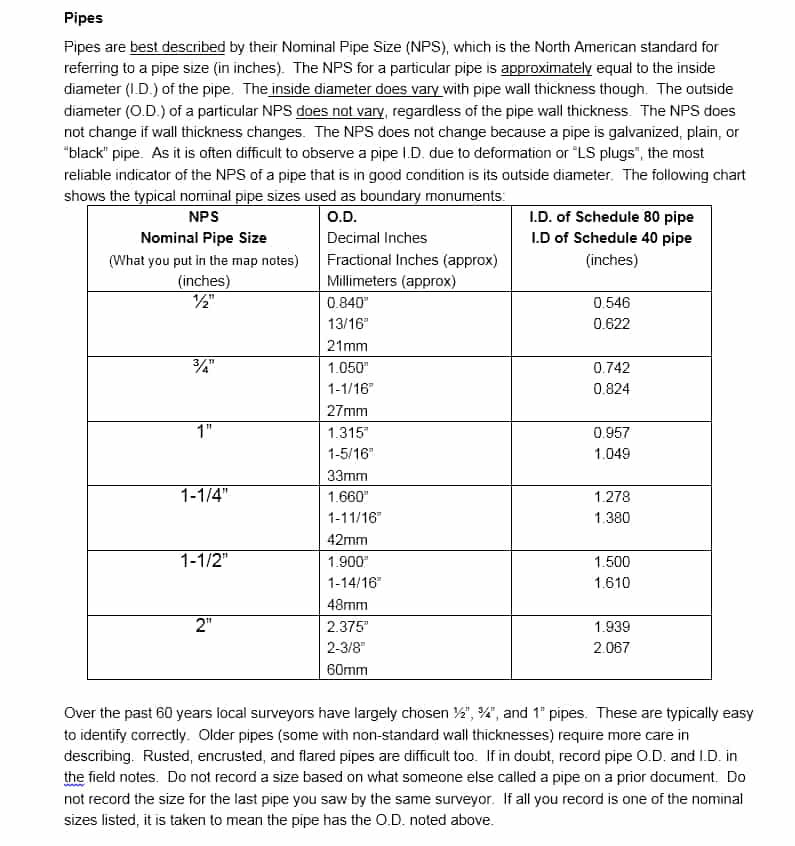

Again referring to the wikipedia article on pipe sizes, a Schedule 40 1/2" pipe (nominal pipe size) has an outside diameter of 0.840" and a wall thickness of 0.109". Doing the math, that makes an inside diameter of 0.622". For all intents and purposes that is 5/8", actual measure. But it's a 1/2" pipe according to the North American nominal pipe size standard. It's a 1/2" pipe according to the manufacturer. Ask any plumber, it's a 1/2" pipe. IMO, it's a 1/2" pipe.

I guess my difference is only, perhaps, what is the primary description. I would think that maybe saying exactly what you found in the ground as the "first" call, and what you think it originated as, as the secondary call, being evidence that you found (or didn't find) the original monument.

But either way, I would definitely include what you see, feel, touch, and measure in your description.

Oregon does have such specifications (5/8" iron rod) and a lot of other states do also. Washington's law is less specific but the 1/2" iron rod is pretty ubiquitous. And has been for about 50 years, maybe more. Same with Oklahoma - to a lesser degree.

Before that almost anything might have been set. Model T axles, rifle and shotgun barrels, whatever pipe or rod. And more. So we are mostly talking about finds of very old monuments.

Nothing like good pipe size talk.

"Doing the math, that makes an inside diameter of 0.622". For all intents and purposes that is 5/8", actual measure."

That is probably what I had. I remember measuring it and thinking that someone was going to think I had mistakenly wrote "iron pipe" when I instead meant "rebar". It was not 1/2" or 3/4". I have never seen anything like it before or after.