Hi All,

Was wondering if anyone knew of any online resources on that cover the creation of linework in Carlson Construction that can be exported as machine control files, specifically for use with a Leica MPC1310 Computer. I understand that the Leica format differs from Trimble or Carlson machine control format. I've done some searching online but have not been able to find anything specific as to the process from creating the linework to importing it into your machine's computer. Leica's manuals don't really cover anything before you import a file into their equipment.

Any help would be greatly appreciated.

What are you trying to create the line work from? What formats will Leica MPC1310 take? I would think you would really want to create a surface model with supporting line work. Also the Carlson menu in the help pull down is very throughout and there are several videos on Carlson website that cover surface model building. Have you ever built a machine control model before?

Surface is an .xml file and the linework is a .dxf file.

DaveJay, post: 419731, member: 12592 wrote: Hi All,

Was wondering if anyone knew of any online resources on that cover the creation of linework in Carlson Construction that can be exported as machine control files, specifically for use with a Leica MPC1310 Computer. I understand that the Leica format differs from Trimble or Carlson machine control format. I've done some searching online but have not been able to find anything specific as to the process from creating the linework to importing it into your machine's computer. Leica's manuals don't really cover anything before you import a file into their equipment.

Any help would be greatly appreciated.

Dave,

There is a lot more to building successful 3d models for machine guidance, than just the software purchase. I suggest you consult with an experienced 3d designer / model builder such as [USER=3408]@Thad[/USER] of Glankler Data Services, LLP , whom answered your question above.

I have attended two classes, both by Leica instructors, but I don't find them thorough. It could be the way the instructors are speeding through the steps or it could be that both times it's been in a rather large group setting but I'm still struggling with the whole process. I do have a private session set up with a model builder next week, I must trying to help myself out by getting the process firmly in my head.

Its really really simple

build your triangle model in C3D hopefully the designer used the same program C3D confirm Subgrade or what ever surface triangulation you want to build

check your model by slicing in corridor or surface subtraction and label depths etc Blah Blah............

extract from surface 3D faces DXF to trimble and topcon leica and use whatever soft to convert 3dface Poly breaks to machine control file a monkey could do this....................

It would be a good idea to place 3D polylines on break lines in C3D ie toe slope and shoulders so doser operator can work

flat surfaces either side of break. pick red its easy to see on doser screen.

Site down with computer wise doser operator in front of model in C3D and spin 3D model around so A1 Computer savvy doser operator

can wrap head around model.

Give Doser operator usb stick of models / Polys load machine specific files into Doser PC and review on screen.

Use same DXF DTM and polys in Carlson Surve CE GPS rover and work one day with doser to confirm model is being loaded right

by computer savvy doser operator.

Check back every day for two hours that GPS doser is working correct pick ing right surfaces on doser controller

Give doser operator push plan tell to push reds into blue using bounded area vols to show that this Red hump will

fill this blue hole +-

Like Lee green says in has every thing to do with The model Builder and a good Computer Doser operator and GPS Grademan.

C3D is a simple program and only takes 5-10 years to master plus you have to know how to design things because

99.9% of engineering drawings today are just feasibility studies and unusable for construction a best or the cost of the paper they are

printed on.

Oh yea wait 120 days to get paid 3 customers last year this one i would like to know how to solve machine controll is simple

Do NOT USE XML the target soft may not support all of the objects in C3D XML output

stick to 3D face and 3 D polylines keep it simple

if you want to stake a pipe pick the 3D polyline fron R12 DXF

a surface use 3D faces from R12 DXF

Peter K

Peter Kozub, post: 419917, member: 375 wrote:

if you want to stake a pipe pick the 3D polyline fron R12 DXFPeter K

can this be done with leica iCON machine control?

ie load a 3dpolyline without a surface and give line and level guidance on the panel?

just from 1 string?

please let me know how. i am reasonably familiar with the Leica machine control but have never worked out how to do this

Most likely with anyone's GPS excavator controller could do it, can't see why Leica could not do it .... such a basic thing

ie

dig ditch for pipe.

clean shape ditch that doser can't do ie to small

call up Leica say you want to dig on line to a 3D poly what buttons do i push pick on screen 3d poly you know

if it can't tell them it should or you want your pounds back and you are going to get trimble or topcon

They will come back with make a 2 meter wide DTM with a alignment down the middle for each pipe

thanks a lot now i have 100 pipes now and have to do the above......DTM + align DTM + align DTM + align DTM + align.......................

@-ing great pick this file this alignment instead of ONE line on screen

You can do it with Carlson Surv Ce GPS rover 7 years or more..

i can pick a 3D poly in 5 button pushes and stake it

I'll take that as a no for now...

Ask Leica

Why ask such a basic question Software specific question on this SITE

I don't work for Leica

You payed for the gear ask Leica

Hi All

i called up Leica and yes a excavator can dig to a 3D polyline i guess pick it on screen on Excavator controller PC

make sure the 300 class excavator is running and GPS control system is on by pushing the green button.

Again

Don't use XML

Don't use XML

Peter Kozub, post: 420512, member: 375 wrote:

Again

Don't use XML

Don't use XML

Out of curiosity, what is (or are) the problem(s) associated with "XML" (and by this, I'm presuming you're referring to the commonly specified LandXML format)? Since the open, well-documented, CAD-neutral and vendor-neutral LandXML structure has been around for over 15 years, it is my belief and understanding that this would be the ideal mechanism for transmitting surface information and that the relatively easy-to-interpret DXF file could be one way of transmitting linework information. Although I'm not familiar with the kinds of data the "Leica MPC1310 Computer" platform can accept, I would be surprised if there isn't a common file format that is shared between the Leica platform and Carlson Construction software.

Peter Kozub, post: 420512, member: 375 wrote: Hi All

i called up Leica and yes a excavator can dig to a 3D polyline i guess pick it on screen on Excavator controller PC

make sure the 300 class excavator is running and GPS control system is on by pushing the green button.

That's not on the current system "iCon" though?

Ladd Nelson, post: 421382, member: 307 wrote: Out of curiosity, what is (or are) the problem(s) associated with "XML" (and by this, I'm presuming you're referring to the commonly specified LandXML format)? Since the open, well-documented, CAD-neutral and vendor-neutral LandXML structure has been around for over 15 years, it is my belief and understanding that this would be the ideal mechanism for transmitting surface information and that the relatively easy-to-interpret DXF file could be one way of transmitting linework information. Although I'm not familiar with the kinds of data the "Leica MPC1310 Computer" platform can accept, I would be surprised if there isn't a common file format that is shared between the Leica platform and Carlson Construction software.

Unless you are using either Leica or SBG sofware - XML is the standard way of bringing in DTMs and also line work to Leiva iCon. It's maybe different on this older system, I don't know.

Using this method the line work can only be used for horizontal guidance though. The level comes from the DTM only.

Incidentally the XML files can be easily edited and unnecessary parts stripped out. I use Notepad++ for this. There are a couple of useful plugins.

Okay

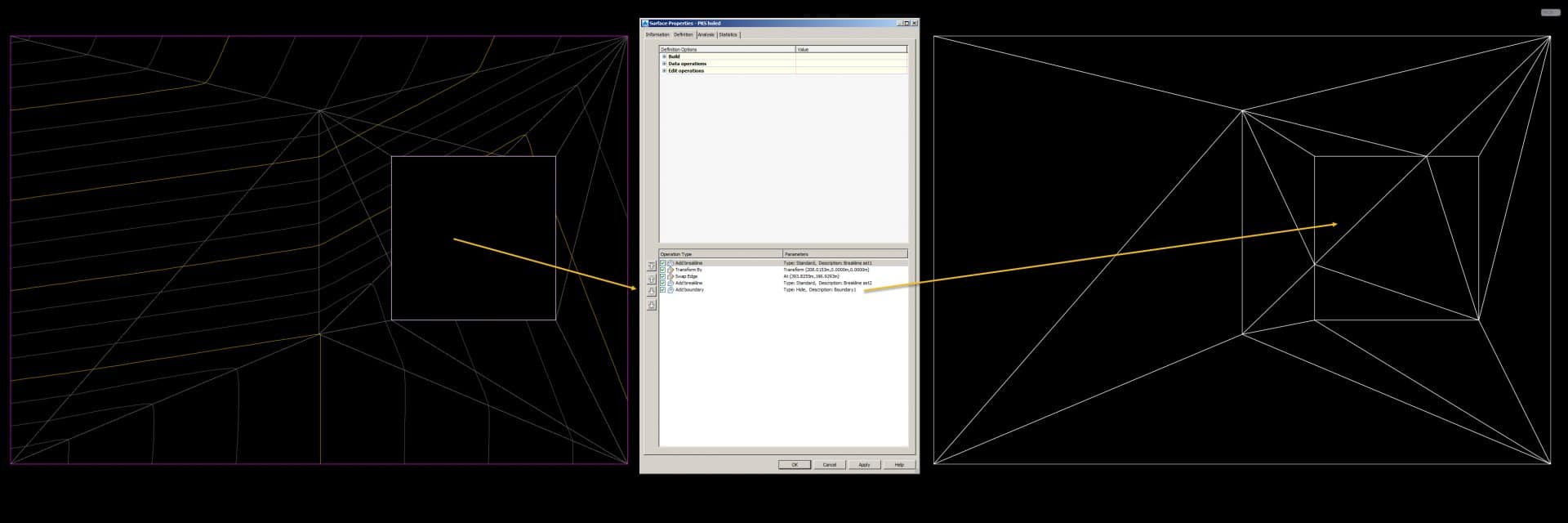

I built a basic surface in 2016 C3D

flipped a few triangles

added a box to make more triangles too

then used the same box to punch a hole in the surface for a swimming pool etc.

XML this surface to Surveyor plus running 5.02 SurvCe and the hole is filled in

The EDIT history is not being applied even thou it is in the XML file

Oh great now how many things are not applied on XML import @!&@%(@!%(

i seriously doubt that ANYONE'S XML import can support all the edit history items in C3D feature lines, paste, Flip, move etc its endless..................

So the best way is to remove the edit history on C3D objects by exploded them to 3D faces and feature line and gradeing objects to 3D polys

and import as simple DXF.

XML import/export is throw around like a baseball as a transfer bucket pure lip service by those who use it little.

I wonder how many jobs have be layed out wrong with XML and vols calced in error oh well

Again don't USE XML

Attached is XML from C3D 2016 Hole is called void in long winded verbose XML

Pete

Here is the XML

-<LandXML language="English" readOnly="false" version="1.2" time="11:31:47" date="2017-04-03" xsi_schemaLocation=" http://www.landxml.org/schema/LandXML-1.2 http://www.landxml.org/schema/LandXML-1.2/LandXML-1.2.xsd " xmlns_xsi=" http://www.w3.org/2001/XMLSchema-instance " http://www.landxml.org/schema/LandXML-1. 2">> http://www.landxml.org/schema/LandXML-1.2 ">

-

<Application version="2014" desc="Civil 3D" name="AutoCAD Civil 3D" timeStamp="2017-04-03T11:31:47" manufacturerURL="www.autodesk.com/civil" manufacturer="Autodesk, Inc."/>

-

-

-

-

-

204.889244967266 455.899672151768 16.431292521696 204.889244967266 486.601917820838 17.105832642458 204.889244967266 500.950523068936 16.920070843382 159.960932663461 500.950523068936 17.144712404901 159.960932663461 455.899672151768 17.727955652001 175.240834612509 455.899672151768 17.651556142256 204.889244967266 455.899672151768 16.431292521696

-

-

237.745317068882 143.543360180222 14.176493281499 217.413177478127 228.076932873111 15.480658601969 237.745317068882 312.610505566001 16.5010673129 120.607929552905 312.610505566001 17.08675425034 156.113306206651 228.076932873111 18.003627016209 120.607929552905 143.543360180222 18.920499781612 237.745317068882 143.543360180222 14.176493281499

-

204.889244967266 455.899672151768 16.431292521696 204.889244967266 486.601917820838 17.105832642458 204.889244967266 500.950523068936 16.920070843382 159.960932663461 500.950523068936 17.144712404901 159.960932663461 455.899672151768 17.727955652001 175.240834612509 455.899672151768 17.651556142256 204.889244967266 455.899672151768 16.431292521696

-

-

237.745317068882 351.55869430184 14.17649328158

217.413177478127 436.09226699473 15.480658601939

237.745317068882 520.62583968762 16.501067312972

120.607929552905 520.62583968762 17.086754250552

156.113306206651 436.09226699473 18.003627016182

120.607929552905 351.55869430184 18.920499781813

204.889244967266 455.899672151768 16.431292521696

204.889244967266 486.601917820838 17.105832642458

204.889244967266 500.950523068936 16.920070843382

159.960932663461 500.950523068936 17.144712404901

159.960932663461 455.899672151768 17.727955652001

175.240834612509 455.899672151768 17.651556142256

-

6 5 10

7 5 6

16 6 9

6 10 9

12 7 6

12 6 11

16 11 6

14 7 13

13 7 12

14 8 7

15 8 14

10 8 9

15 9 8

16 9 15

16 12 11

16 14 12

14 13 12

16 15 14

I don;t use civil3d, but I have heard that "void" triangles are discarded when importing to the Leica iCon machine control panel. I heard this in connection with another software package (LSS).

But I have no experience of this. If I delete triangles in my software then they don't appear in the XML at all.

Seems to me that Civil 3d has a problem with xml. But as you said if explode as 3d faces and then export as a surface xml.

My software doesn't have a problem exporting my surface as an xml file. Nothing is lost or changed.

I use Terramodel for surface building.

If your client asks for an xml of the surface, what do you do? I send an xml of the surface if that is what the client wants.

Hi Thad

Send them DXF R12 3D face and some 3D polys or they have to send from there

device XML out so you have to waste your time to see if there XML in is working *%$*%##*.

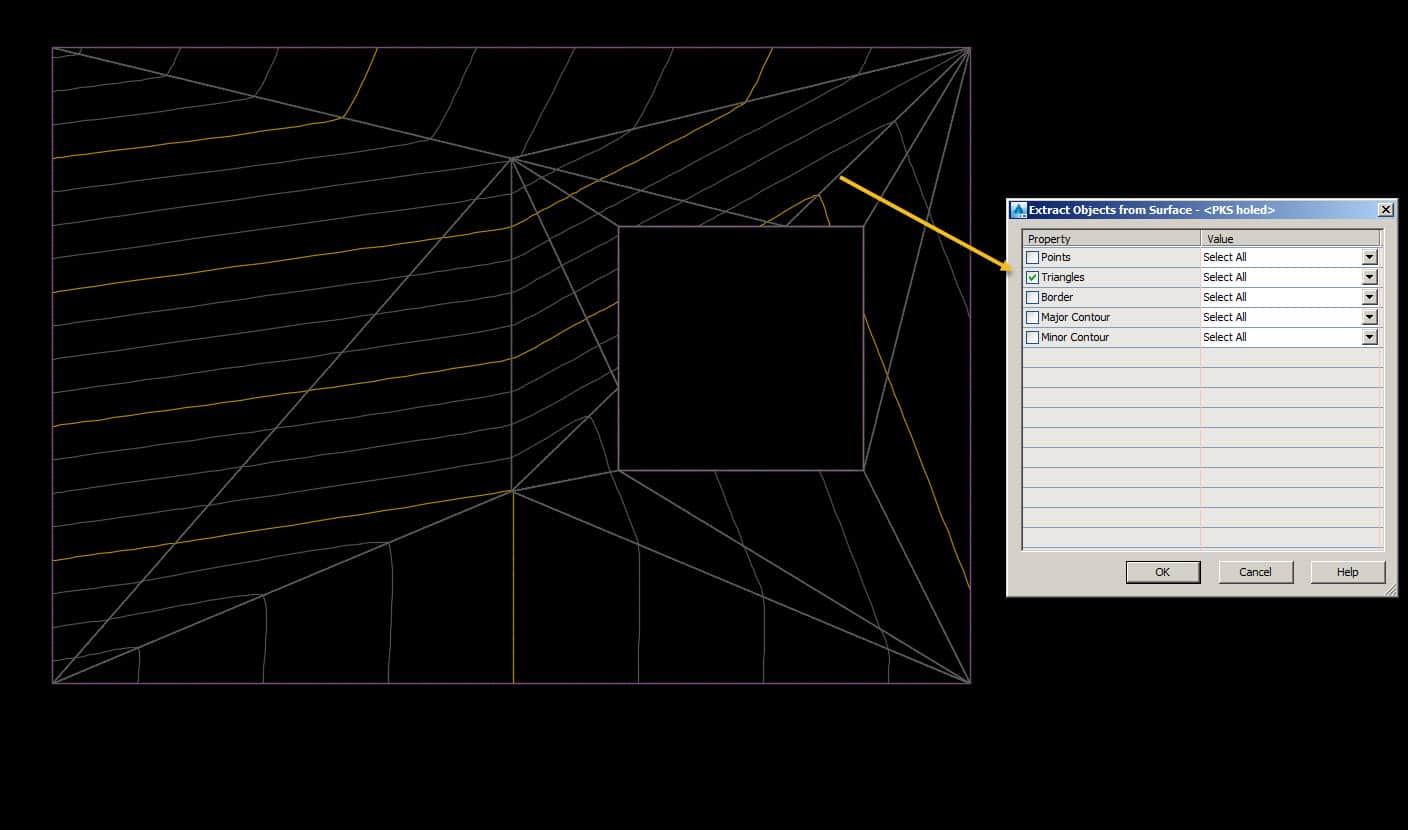

Explode surface and select 3d faces and wblock to R12 DXF or use C3D EXTRACT objects shown

below is a bit slicker. There a about 3 ways to wblock out the 3d faces to r12 DXF

XML is crappy tool to send data between Design Programs IE C3D Inroads Etc but the only one i guess.

C3D output is fine is the target program that is the problem since autodesk is adding new smart objects all the time. this

means that XML export has to include these new objects and the target soft has to interpret these objects properly so the target

software XML programmer has the difficult task of supporting these objects PROPERLY what a mountain of a task.

If i export by XML from C3D and then imported the same XML the data objects would most likely survive the round trip.

Its the target soft that is the problem for C3D makes the XML a moving target for the import programmer.............. yikes

In C3D i use extract objects from Surface or Corridor and the wblock as DXF R12 takes about 30 seconds

i then copy to Carlson surveyor plus this dxf and import 3d face to dtm

OLD SIMPLE RELIABLE DXF

The slick part is i can open the dxf on my PC using C3D via USB and look at the DXF on carlson Surveyor +

try to do that with XML as a QC.

The same can be done for a corridor extract feature line IE gutter line CL etc as 3D polys

When a client's asks me for a specific type of file (because that is what the equipment reads) then that is what I send but make sure the way their equipment will read it is the same as I send it.

It's not my job what he does after I send it. If they want the surface as dxf, ttm, tin, dtm, points file, etc. I send it to them that way.

Also, I am not sending them for design purposes but for machine control which is what the topic was all about.