Started surveying in 1971. First couple of years was nothing but "chaining" with chrome clad, calibrated steel tapes. No dragging of the tape on the ground, eyeballing line, hand level, spring balance and temperature correction with the "good chain" for boundary and control work.

Lots of technique gleaned from the old guys with string burns on their necks. I remember Monty telling me, his rear chairman, to hold the "ped of your hecker" while he held the top of his head for level.

With two guys in unnatural positions, each monitoring the end of a swinging plum bob and trying to maintain that 17 lbs. of pull, it was tough to know when the important guy was "Good". Yelling GOOD or POINT or SET or YEAH or whatever one used always disrupted whatever stability I was able to maintain for those precious few seconds during important measurements. Someone came up with the technique of clicking the "chain" at the instant one was, indeed, GOOD. We used the fingernail on our forefinger to gently pluck the tape and both the sound and the physical pluck would zoom down the chain to the recipient. Worked like a charm.

I must have done dozens of miles that way. Give me RTK anyway.

JA, PLS SoCal

Hijacking the original post a little here for which I apologize:

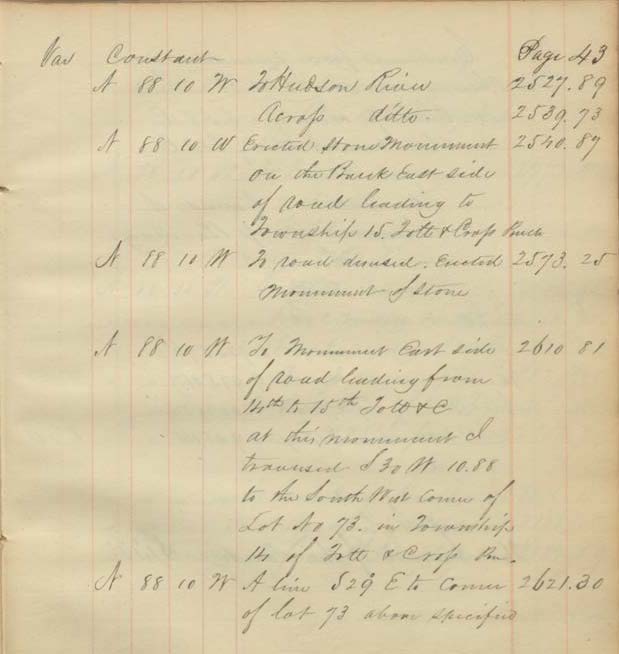

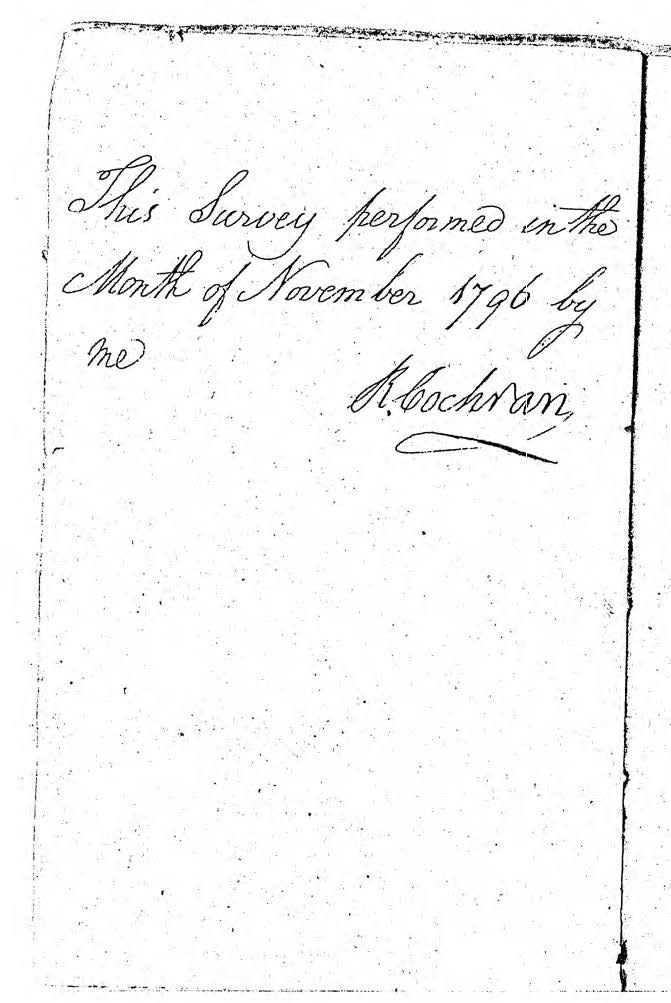

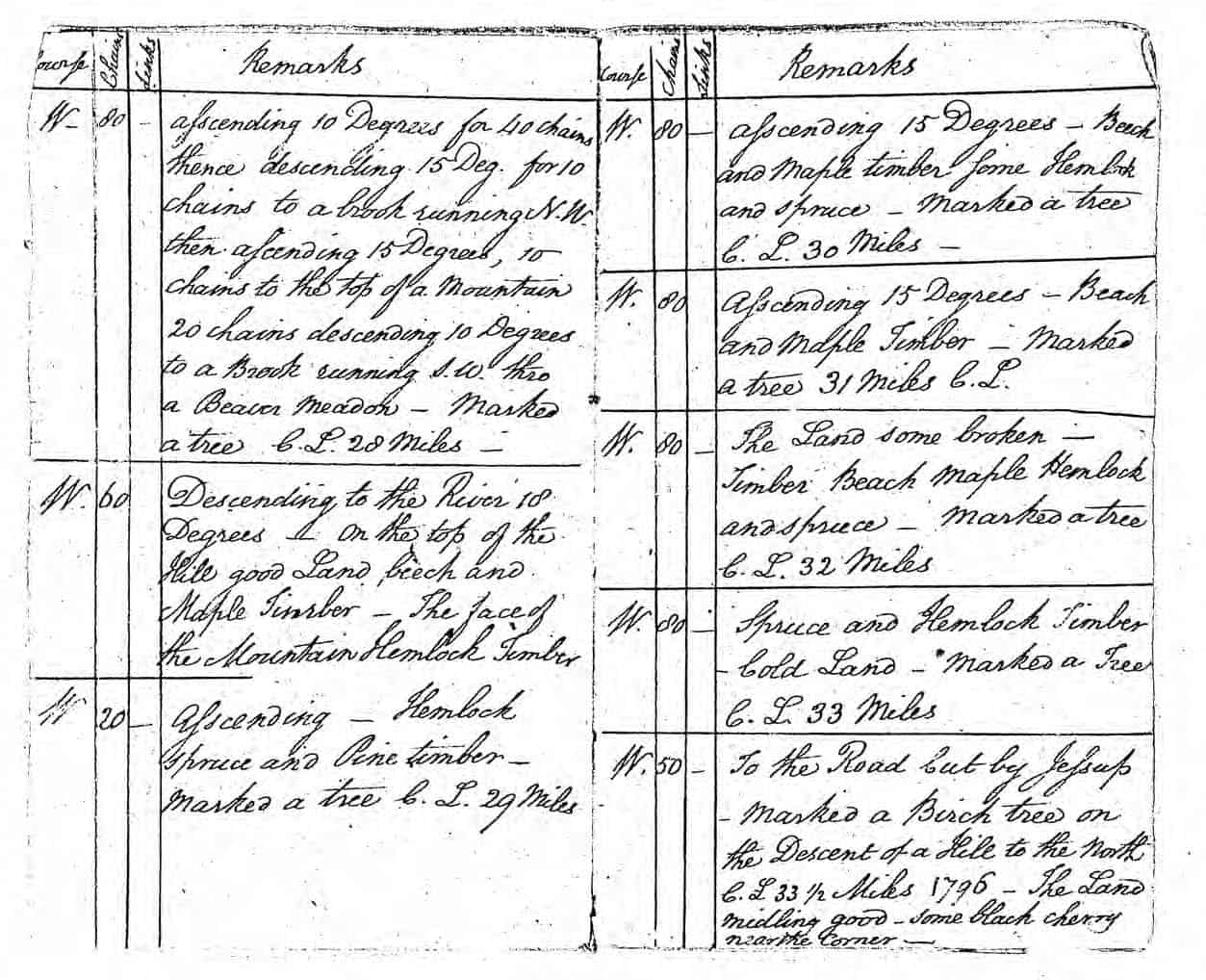

Here are a couple of images from another field book (actual photocopy here) from a survey run to intersect the one I posted before. Once again slope chained with NO allowance given in the notes. The first one is from 1844 and the second from 1796. Note in the 1796 notes they start the tally again after each mile.

Jim

JOHN NOLTON, post: 384518, member: 225 wrote: paden cash I started surveying in 1962 and I used the command "Tape" as it is the correct terminology to use. I have used it right up till I retired in 1997.

JOHN NOLTON

I bet you were a geodetic engineer too!

paden cash, post: 384538, member: 20 wrote: Just a local thing I guess.

As an instrument man I was taught to holler "good!" when the person to which I was giving line to was correctly on line. We got a new PC once and I suppose he wasn't accustomed to that particular regime. Every time I would wave my hands and announce "good"....he'd reply "why thank you!"

Naw, its not a local thing! Some things should not change, and yelling 'CHAIN' is one of them. Land Surveying is Land Surveying, not geometronics and when there are a couple of us we are still a 'Survey Party"! my 2 cents, Jp

John Hamilton, post: 384588, member: 640 wrote: (who remembers "raise for red"?)

I do! Jp

Tom Adams, post: 384618, member: 7285 wrote: Even when edm's were popular, in every truck we still carried our chains (tapes) around. We were paranoid about doing shorter distances with an edm; especially with laying out a building. We always checked and double-checked the distances and the diagonals until it was right on (in our mind). we would mark the hub and check and check before we finally put the tack in. We were probably a bit too paranoid.

At the last building I ever staked, back in 1990 or so, we set the corners and had to come back the next day to finish off the offsets. The contractor came out and said something like "I got to hand it to you guys, I checked your measurements and you were right on. I usually have to come out and bump the hubs around to get them right on after the surveyors stake it." I took the compliment but in my mind I was thinking how he probably has taken some perfectly-staked buildings and tweaked them around wrong. Why in the world would you hire a surveyor when you can stake it out better by yourself?

I staked to slabs for shops on my property. Both poured by different concrete contractors and both contractors adjusted my stakes. I had to adjust the buildings to fit the foundation in both cases.

Oh the memories of my hand getting cut when someone jerked the chain with out yelling hold it good or pull it tight. Didn't really ever use the brass knuckles except for longer traverses. always used a 100 or 200 foot steel chain.

Here are the instructions from my alma mater...

DDSM:clink::beer::clink:

About two years ago I insisted on bringing out our 100-foot chain to verify the distances between footings on a couple of highway sign bridges (there is virtually zero tolerance in staking these). I still consider the chain a useful tool today if perhaps for limited purposes.

Berk Blake PLS CA, post: 384520, member: 7998 wrote: We used to use the 300 foot canyon tape, 1/8" wide that was compared to the Lovar tape that had been calibrated by the fed's.

I was going to ask you if you meant "invar" instead of "lovar", but to be safe I looked up "Lovar Tape".......whew. Now I don't have egg on my face (except that I just wrote about my ignorance...)

SellmanA, post: 384684, member: 8564 wrote: About two years ago I insisted on bringing out our 100-foot chain to verify the distances between footings on a couple of highway sign bridges (there is virtually zero tolerance in staking these). I still consider the chain a useful tool today if perhaps for limited purposes.

When I did road work I staked a jillion footings for overhead sign lattice braces and uprights. And you're correct, it's best to get the footings and plate mounts on the gnat's nut. Something that we ran into time and time again was the deformation of the shop built sign with temps and shipping. Early on the structure fabricator would call up bitching that the footings weren't correct. We'd show up and eventually get them to understand (yes, with a steel tape) the footings were correctly positioned, it was their 2 ton, 130 degree "sitting in the sun all day" structure that was deformed.

Most placing crews got good at waiting until early morning and tweaking them a bit as they mounted them to the footings. I have seen a weld or two split during some "aggressive" positioning.

I remember they eventually went to a design that involved first mounting the vertical members and then the cross lattice mount was mechanically attached. A tidier affair for sure.

The current sign bridge design (at least in the last contract) gave the contractor the option of either setting the entire structure whole, or setting the vertical members first and bolting the horizontal pieces together.

"Tom Adams" said

"I was going to ask you if you meant "invar" instead of "lovar", but to be safe I looked up "Lovar Tape".......whew. Now I don't have egg on my face (except that I just wrote about my ignorance."

No, Tom you didn't show ignorance, I believe you showed curiosity and the gumption to look for the answer.

I also came in at the end of the taping era, though we did call them "chains," and conducted "chaining," and I was classified as an "apprentice chainman." But we didn't use chaining/taping pins -- we used nails, or tacks, or hubs and tacks. And I don't think I ever taped farther than a 1/4 mile except for rough work.

I was at the end of that era too.

Learned to chain and throw in school. Temp, tension, sag calcs

First job - Ozarks - Topcon 2nd generation TS

Moved back to Louisiana and the company that I took a job with used 30" K&E transit/stiff leg tripod and 200' & 100' on reels.

For traverse and baselines, double chain the line, if

Something was not right, do it again. Plumb bobs. Everything is relatively level here. No steep slopes.

I man gave line and took notes. Ground soft, no rocks here. Made indent with bob. Mark spot with twig/flagging and/orflagged nail.

Used keel on edge of road or on concrete.

It was challenging in wetlands and marsh. One had to get innovative.

Laid out three subdivisions using transit/tape.

After awhile, we lobbied the owner for a TS. Got a Topcon GTS 2b

We used a technique called "double chaining".

As we chained down a paved street we placed to red pencil dots about 0.2' apart, online.

In chaining book, kept two columns of the running totals.

When we got to the end of the, line the two columns totals should be equal.

When pulling ties to a point we also kept a metric chain.

Did the measurements in feet & meters (then converted to feet)

This cut down on reading errors.

Always used a balance and temperature correction. Everybody carried a thermometer.

Always chained downhill so rear chainman was on ground, head chainman used plumb bob.