The Delaware RiverÛÒTurnpike Toll Bridge is a four-lane steel arch-shaped continuous truss bridge that connects the Pennsylvania Turnpike's East-West Mainline with the main trunk of the New Jersey Turnpike. It was opened in 1956. I guess it has a 60 year life cycle.

http://www.fox29.com/news/local-news/230472229-story

Paul in PA

Paul, you missed your calling as a headline editor. 😀

I've been over that bridge a few times although last time I went around through Philadelphia to cut down on the road tolls.

Gas is cheaper but the tolls make a trip of similar length comparable cost to California.

East Coast bridge tolls can require a second on the house, California bridge tolls tend to be half or less.

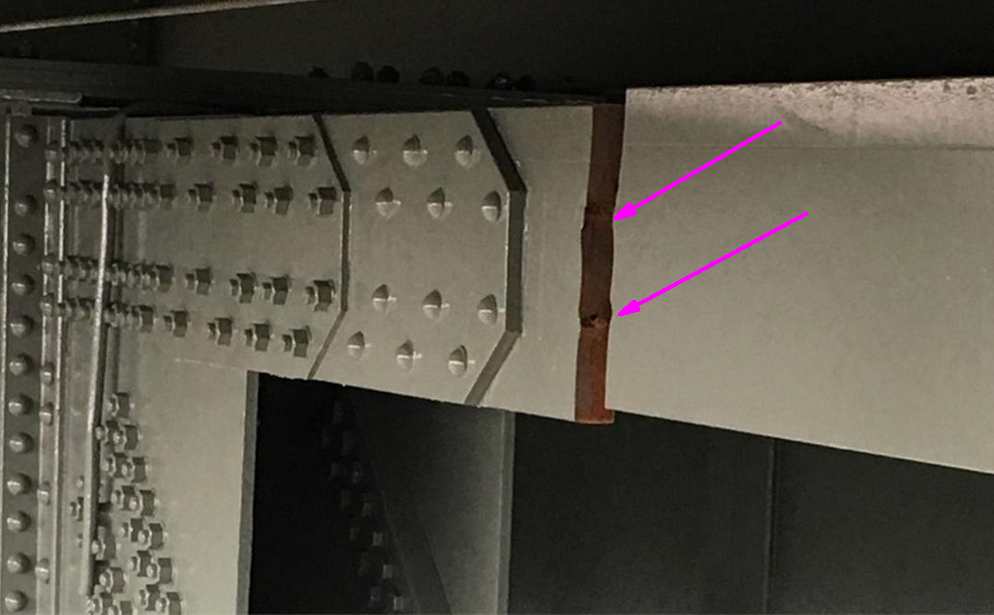

Update, photo of crack:

This bridge will be closed for weeks.

From what I see the 14" structural section used as the top member was predrilled/prepunched for rivets that were not used, but instead the holes were surface plug welded and those holes became stress concentration points. The fact that the crack has opened up as more than a 1 1/2" gap as part of a series of connected Warren Trusses that span more than 1/2 mile means that the design for the repair may first begin at a point a thousand feet away.

Paul in PA, PE, PLS

I had that bridge confused with the other one to the south.

It's weird how you're going along on I95 northbound when suddenly you realize you are southbound on some other interstate, like what? It's like San Jose except the whole state is like that.

Paul in PA, post: 410563, member: 236 wrote: Update, photo of crack: .....

I wouldn't characterize that as a "crack". That's thing is broken.

Not good.

Dave Karoly, post: 410617, member: 94 wrote: I had that bridge confused with the other one to the south.

It's weird how you're going along on I95 northbound when suddenly you realize you are southbound on some other interstate, like what? It's like San Jose except the whole state is like that.

Just don't slow down to try and figure out where you're going! We hate that! And stay out of the left lane unless you're going 120mph!

Paul in PA, post: 410563, member: 236 wrote: From what I see the 14" structural section used as the top member was predrilled/prepunched for rivets that were not used, but instead the holes were surface plug welded and those holes became stress concentration points

Cripes, are all the rest of the similar connections plug welded? Thats going to be a huge problem to repair, if it can be.

Dan Patterson, post: 410637, member: 1179 wrote: Just don't slow down to try and figure out where you're going! We hate that! And stay out of the left lane unless you're going 120mph!

Just the opposite in Florida, everybody in the left, center, and right lanes drive 25, 35, and 37mph respectively while applying makeup, texting, and eating. (Or all three at once) This only leaves the right shoulder for us 38 to 120mph drivers. 😉 (kinda fun too)

Where do you see plug welds?

Looks like hot rivets and structural bolting.

I wonder if that member is classified as fracture critical and when the last time it was inspected for cracks.

It will be interesting to see the cause and fix. I wonder if they could load an adjacent span and cause the steel gap to close back up for temporary repairs (something like a full pen weld sandwiched with bolted plates).

imaudigger, post: 410653, member: 7286 wrote: Where do you see plug welds?

Lower right on the cross beam.

FL/GA PLS., post: 410677, member: 379 wrote: Lower right on the cross beam.

Appear to be rivets to me, but the lighting is weird on the photos. It looks like a recently painted bridge.

I'm reading that the going theory is that several holes were mistakenly drilled in the fractured member and filled with a plug weld as a repair.

They are opposite of the last two rivets and look to be the right spacing. Makes you wonder if they laid the entire pattern out wrong and plug welded more than two.

"Karl Frank, professor emeritus of engineering at the University of Texas at Austin, said Monday he suspects holes were mistakenly drilled into the truss during construction and were filled with plug welds that were defective and eventually gave way."

Read more here: http://www.newsobserver.com/news/technology/article128155659.html#storylink=cpy

imaudigger, post: 410680, member: 7286 wrote: I'm reading that the going theory is that several holes were mistakenly drilled in the fractured member and filled with a plug weld as a repair.

They are opposite of the last two rivets and look to be the right spacing. Makes you wonder if they laid the entire pattern out wrong and plug welded more than two.

After reading your link and lookin' at the shear in your pic, I agree and was "misinformed" (I think that's also called "spinning" aka: trying to weasel out of something) prior to my previous post. Or as SWMBO would say "WRONG". I think I might be too old to post anymore, sigh.:p

FL/GA PLS., post: 410693, member: 379 wrote: After reading your link and lookin' at the shear in your pic, I agree and was "misinformed" (I think that's also called "spinning" aka: trying to weasel out of something) prior to my previous post. Or as SWMBO would say "WRONG". I think I might be too old to post anymore, sigh.:p

Merely "alternative data", that's all...

Mark Mayer, post: 410633, member: 424 wrote: I wouldn't characterize that as a "crack". That's thing is broken.

I have some clamps and a bottle of elmer's glue.

imaudigger, post: 410680, member: 7286 wrote:

"Karl Frank, professor emeritus of engineering at the University of Texas at Austin, said Monday he suspects holes were mistakenly drilled into the truss during construction and were filled with plug welds that were defective and eventually gave way."Read more here: http://www.newsobserver.com/news/technology/article128155659.html#storylink=cpy

Well, one thing for sure, some expert from Austin will come along and tell you that you screwed up.;)

...said Joe Martin, an engineering professor at Drexel University in Philadelphia. ÛÏItÛªs incredibly unusual for steel to break like that. Pieces donÛªt break. They stretch, they twist, they give you some warning to get out of there. Û? Fractures are the bridge engineerÛªs nightmare."

There is a mixture of high-strength bolts and rivets in the pictures. Since the bridge is approximately sixty years old the bolts may have been part of maintenance and that is when the plugs were made.