It's been a week since I hastily replaced my dead Allegro CX with a Carlson Surveyor+. I had too much work to do to wait for a Surveyor2 -- they were on backorder everywhere I checked -- so I decided to make do with the superseded +. However, I quickly learned that the built-in bluetooth wasn't designed to operate a robot at any significant distance, so I did an emergency graft of the Parani BT radio from my Allegro onto the Surveyor+. It wasn't pretty, and it was mechanically vulnerable, but it got me through the week:

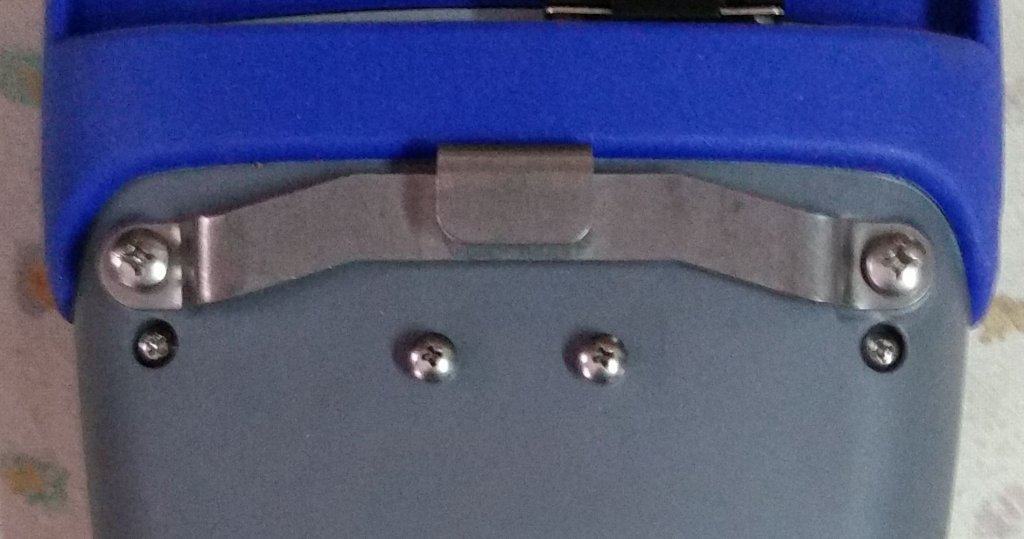

While productively using this cobbled-together monstrosity during the day, in the evenings I began assembling and adapting components to produce a more robust solution. When I got the Allegro in 2011 it was already about 7 years old, so I didn't mind hacking it extensively to incorporate the Parani. But this Surveyor+ is brand-new and under warranty, so I decided to take a more conservative approach. (There's not enough room inside the case for the Parani anyway.) The obvious mounting choice were the two threaded holes securing the tripod hanger:

I wanted a little more room between the stock bracket and the case for hardware, so I made a new one out of 3/4"x1/8" aluminum and drilled a couple of mounting holes in it:

I bought a die-cast aluminum box to house the Parani and cabling, and drilled corresponding holes in it:

Since the DC will often rest on its back, I didn't want the box exerting too much leverage on the mounting bracket, so I glued a couple of pieces of ABS plastic I had lying around, shaped one face to fit the contour of the DC, and drilled a couple of holes to clear the mounting screws that retain the hand strap that I don't use. The fit of the plastic over the screws and against the aluminum bracket is snug enough that I decided that it doesn't need any other attachment -- the radio box will keep it from going anywhere if the friction fit isn't enough to keep it in place.

The ABS cushion installed. Note the two holes that I originally drilled in it, thinking that I'd bolt or rivet it to the bottom of the radio case. I subsequently decided that's not necessary.

The radio box installed. The cover is visible to the left, and the radio (sans antenna) above it. The power connector in the upper left is from the old battery arrangement, and won't be required for this installation.

The radio will be fed com and power by means of a flat 9-conductor cable from the COM1 port, so I drilled and filed a slot for it. (Looks like I got it a little crooked.)

This is the wiring diagram. The component joining Pin 9 of the radio with Pin 4 of the COM1 port is a Schottky diode, which Juniper (the manufacturer of the Surveyor+) advises as reverse polarity protection, since Pin 4 initially comes up negative before the port is initialized. Although Pin 4 is non-standard for +5v on a COM port, that's the way Juniper wired it. The diode may be unnecessary -- the Parani may have the protection built in -- but I didn't want to take a chance.

The box with radio installed and wiring spliced. The diode is hidden by the the red heat-shrink at the left side of the splice.

Everything installed, and foam packed in to keep things from rattling around. The radio itself is secured by the antenna. I put an O-ring on the antenna stub before inserting it into the mounting hole to provide a more vibration-resistant installation. The cable exits the top of the box and is terminated in a right-angle 9-pin D-sub connector, which is shown plugged into COM1 of the Surveyor+. The Schottky diode is more clearly visible between the red heat-shrink in this photo.

The (nearly) finished installation:

I say "nearly" because I'll probably put some silicone around the cable where it enters the box.

This radio solution markedly increases the bulk of the DC, but all of the increase is on the back, so it doesn't interfere with operation. The antenna now nestles close to the pole instead of sticking out ahead of it, and the radio itself is well-protected by the box. I still need to come up with a tripod hook for those times when I want to take reflectorless shots from the gun, but 99% of the time I run robotic from the pole, so the hook can wait.

Jim, out of curiosity, would your DC50 run your robot? And if it would, would the bluetooth in the DC50 have the range you were looking for? The reason I ask is because I am toying with the idea of acquiring a robot and running it with my DC50.

Edit: nice job on the radio case, by the way.

Jim,

Excellent job!

Jimmy

Boy you're clever! I would have used Duct tape.:good:

Jim,

That is alllright, a fine job!

Alan Cook, post: 323439, member: 43 wrote: Jim, out of curiosity, would your DC50 run your robot? And if it would, would the bluetooth in the DC50 have the range you were looking for? The reason I ask is because I am toying with the idea of acquiring a robot and running it with my DC50.

I spent a little time trying to get the DC50 to run my robot -- a Leica TCRA1102plus -- but wasn't successful. I don't recall what the problem was, but since the Leica came with an Allegro CX that was all set up to run it, it was more expedient to switch platforms. I have no doubt that the DC50 radio range would have been fine, especially with an external antenna installed, since the DC50 also uses a Parani. (I think it came with a Parani SD100 rather than an SD1000, but I don't recall what the difference is, and it would be easy to swap one out for the other anyway.)

Just curious, but if the Parani can draw power through the com port, then why did you need the battery for the original set-up?

Surveyors are pure cobblers. We put stuff together, and make it work. The world was not made for surveyors. So, we adapted our stuff. The original wire, used to make chains was not made for that purpose. It was an adaption. I really cannot think of very much that was purely made for surveying. From the ground up. And, I will probably get worse. Much worse!

The Pseudo Ranger, post: 323464, member: 18 wrote: Just curious, but if the Parani can draw power through the com port, then why did you need the battery for the original set-up?

The Surveyor+ supplies +5v to Pin 4 of the COM1 connector, but the Parani needs it on Pin 9 unless an external power source is provided. I *could* have rigged up a short crossover adapter, but it would have added more length and fragility to the temporary arrangement, so I opted for the batteries and bungee cords while awaiting a more permanent solution.

This would increase costs but did you ever consider using 2 Parani on your belt with a power supply? A short range model that connects with bluetooth to the DC conneccted by short cable to a long range model that connects to the TS. Even though it would cost more it might be a more elegant and sturdy solution. I think this was an option on the package that Hayes sold.

Steve Corley, post: 323490, member: 23 wrote: This would increase costs but did you ever consider using 2 Parani on your belt with a power supply? A short range model that connects with bluetooth to the DC conneccted by short cable to a long range model that connects to the TS. Evne though it would cost more it might be a more elegant and sturdy solution. I think this was an option on the package that Hayes sold.

It's an interesting idea, but I've found the DC-mounted solution to be very workable, so I'll probably stick with it. The obvious downsides to a belt-mounted repeater are more batteries to keep charged, more stuff to snag on brush, and - perhaps most significant - reduced range due to antenna location.

I'd be interested in hear about the real-world experience of someone using the arrangement, though.

P.S. I bet Norm Larson could produce a much more elegant package than I did. This would seem to be an ideal application for 3D printing. If I ever get any spare time, I'd like to dip my toes in that pool.

The use of the ribbon cable is brilliant, hats off to you on that one. I am going to steal it, 😀

One of my favorite parts of these detailed work photos from Jim Frame are the baby changing sheet covers in the background that he has no doubt repurposed now that his baby has grown up.

Brad Ott, post: 323564, member: 197 wrote: One of my favorite parts of these detailed work photos from Jim Frame are the baby changing sheet covers in the background that he has no doubt repurposed now that his baby has grown up.

The dirty little secret about that is that I have 2 large workbenches in my garage and a large desk in my office as workspaces, but all are so thoroughly covered in stuff that I do a lot of little projects on top of the dryer in the garage. I use the rubberized baby mat to protect the dryer paint.

One of these years I'm going to clear off my desk and the workbenches, but there's always something "more important" to do.

Jim Frame, post: 323571, member: 10 wrote: One of these years I'm going to clear off my desk and the workbenches

I resemble that remark.

My wife is slowly coming to the realization that when I'm gone she's going to need a dump truck to clear things out. Just about every piece was saved for some potential use, not out of neglect, but of course I'll only get around to a small percentages of those projects.

Bill93, post: 323580, member: 87 wrote: My wife is slowly coming to the realization that when I'm gone she's going to need a dump truck to clear things out. Just about every piece was saved for some potential use, not out of neglect, but of course I'll only get around to a small percentages of those projects.

We might be brothers...

I got a surveyor+ back in January and similar to you I figured out that it wouldn't connect very far from the instrument, I was lucky because I was able to trade it in for the Surveyor2. (Allen Precision). But I'm impressed with what you created. Good job

.jpg)