Hello, I am being told from a Trimble service center that they can no longer replace the internal batteries in the ACU controller.

Sounds like per-determined obsolescence.."gee we can't get that shape battery anymore".

Has anybody had luck sending the ACU to a company specializing in batteries?

imaudigger, post: 428438, member: 7286 wrote: Hello, I am being told from a Trimble service center that they can no longer replace the internal batteries in the ACU controller.

Sounds like per-determined obsolescence.."gee we can't get that shape battery anymore".

Has anybody had luck sending the ACU to a company specializing in batteries?

I had mine changed out last year at precision midwest,

Jim

I called Midwest Precision and they said they have not been able to replace the battery in the ACU for at least 3 years.

Sounds like all Trimble authorized repair centers are prohibited from using non-Trimble parts.

I will be running into this same problem with the power rod...battery discontinued forcing you to buy new rod and prism.

I be going with a different yellow brand next time because of these issues. Was 2008 really that long ago?!

The plan is to go in there with my sleeves rolled up and replace the battery myself using a custom made battery pack.

imaudigger, post: 430684, member: 7286 wrote: I called Midwest Precision and they said they have not been able to replace the battery in the ACU for at least 3 years.

Sounds like all Trimble authorized repair centers are prohibited from using non-Trimble parts.I will be running into this same problem with the power rod...battery discontinued forcing you to buy new rod and prism.

I be going with a different yellow brand next time because of these issues. Was 2008 really that long ago?!

The plan is to go in there with my sleeves rolled up and replace the battery myself using a custom made battery pack.

they gave you a line of bs. the problem you will have is you need the old special dos program to download the internal programs before removing the batteries the to upload back. This was a different program than the one to upliad/dowMaybe it can be done if you can supply continous power during the swap.

They told me that there was no need to worry about maintaining constant power and that it was just a matter of swapping the battery out (once I source a battery), which makes sense considering the thing is dead every time I unplug it.

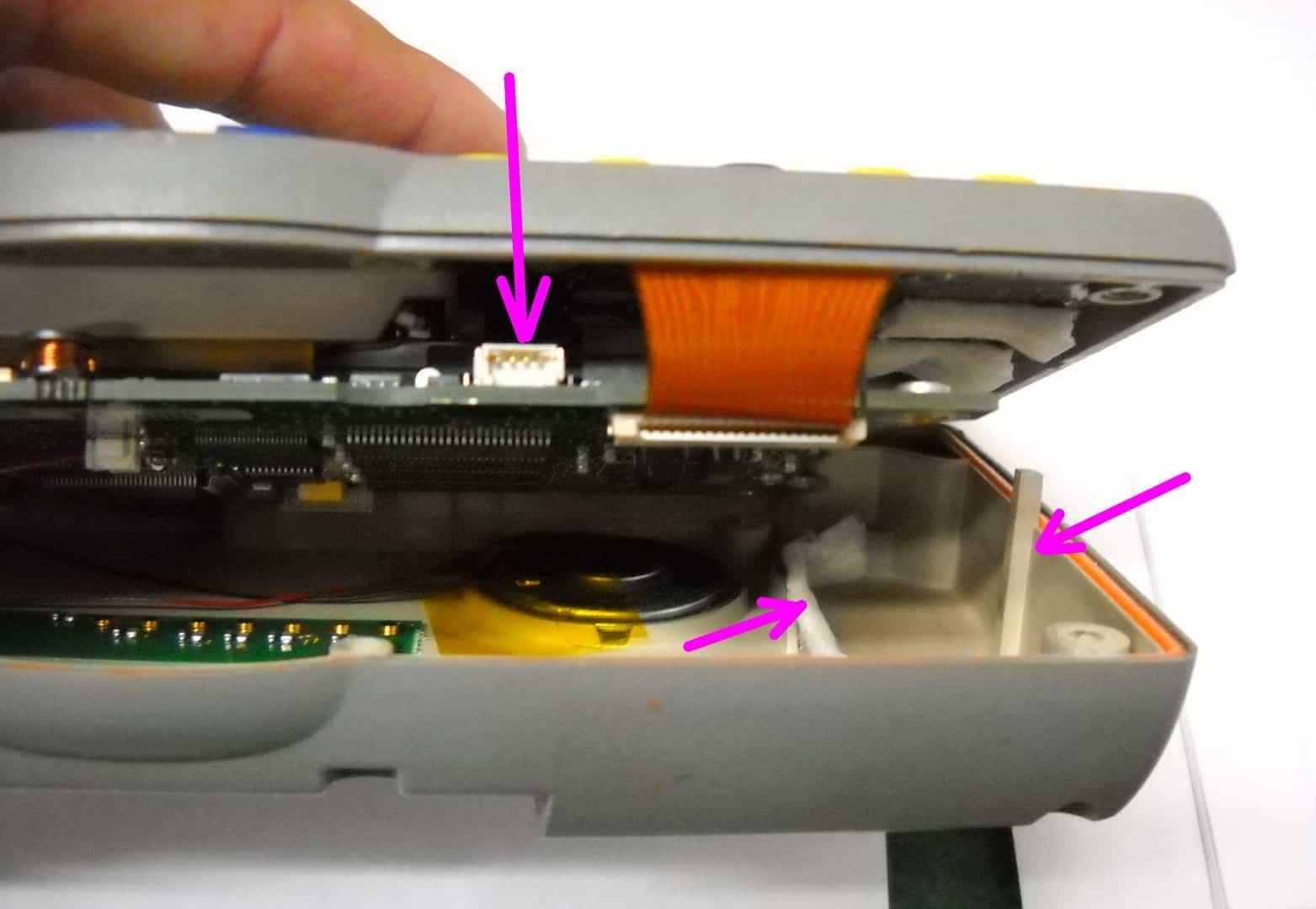

So I took all of the screws out of the back of the ACU and separated the case.

In doing this, I noticed that 4 of the screws only served to hold a circuit board in place, so I replaced these 4 screws and tried to separate the case again. This time it would not open very far due to short ribbon cables....so I took all the screws out again.

This allowed me to separate the case about 1", which was enough to spy the battery and battery connection.

I used an exact o knife tip to gently pry the power connection apart.

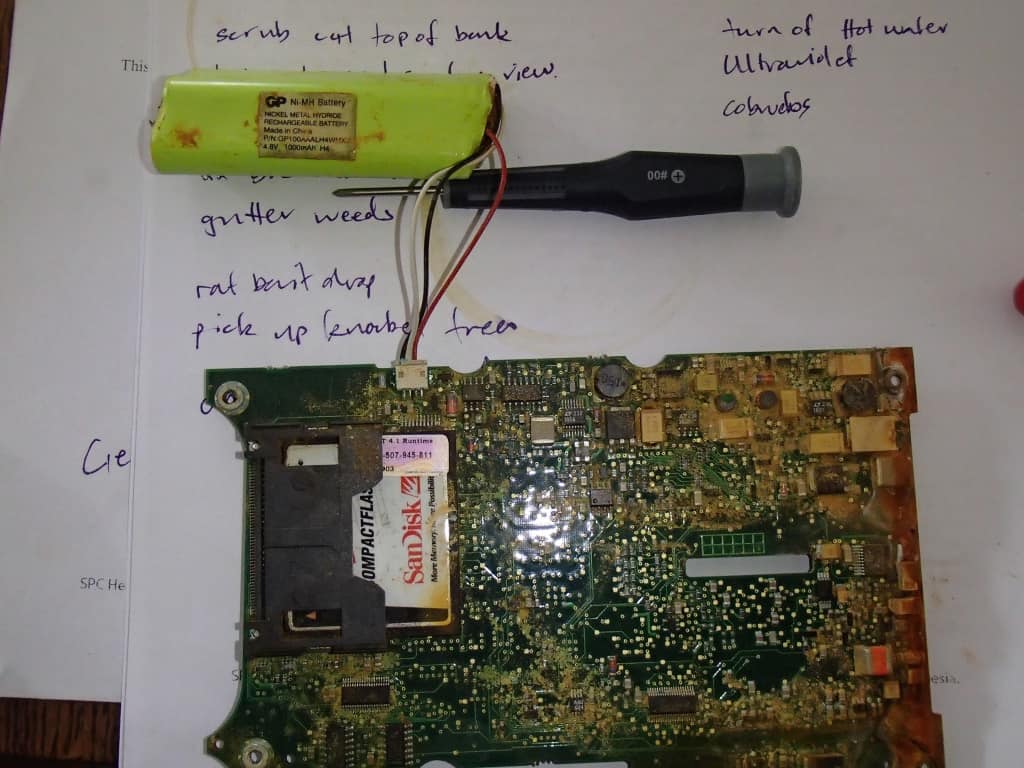

Here is the "special" battery that Trimble is no longer able to get manufactured.

I will be looking into the part number...then cutting the shrink wrap to look for individual battery part numbers.

Anybody familiar with a battery pack similar to this?

Spoke with Batteries Plus and they said they could build this battery using NiHM AAA for about $20.

NICE!

and that's what it is all about. The manufacturers want to make stuff, not support it. They don't go out of their way to make it painful, but, why not a little gouging. When I bought my S6, I didn't buy their chargers assuming they were over priced and not as functional as I could make. I was correct. I made an S6 charger for around $45 and they wanted around $500

imaudigger, post: 430793, member: 7286 wrote: Spoke with Batteries Plus and they said they could build this battery using NiHM AAA for about $20.

NICE!

Is it correct that in this case (unlike Geodimeter CU's) you don't need to keep the ACU board powered so as not to loose the software?

Richard Imrie, post: 430810, member: 11256 wrote: Is it correct that in this case (unlike Geodimeter CU's) you don't need to keep the ACU board powered so as not to loose the software?

I'll let you know next week when I plug the new batteries in. I'm pretty confident that it will fire up just fine (considering the battery has gone completely dead numerous time before).

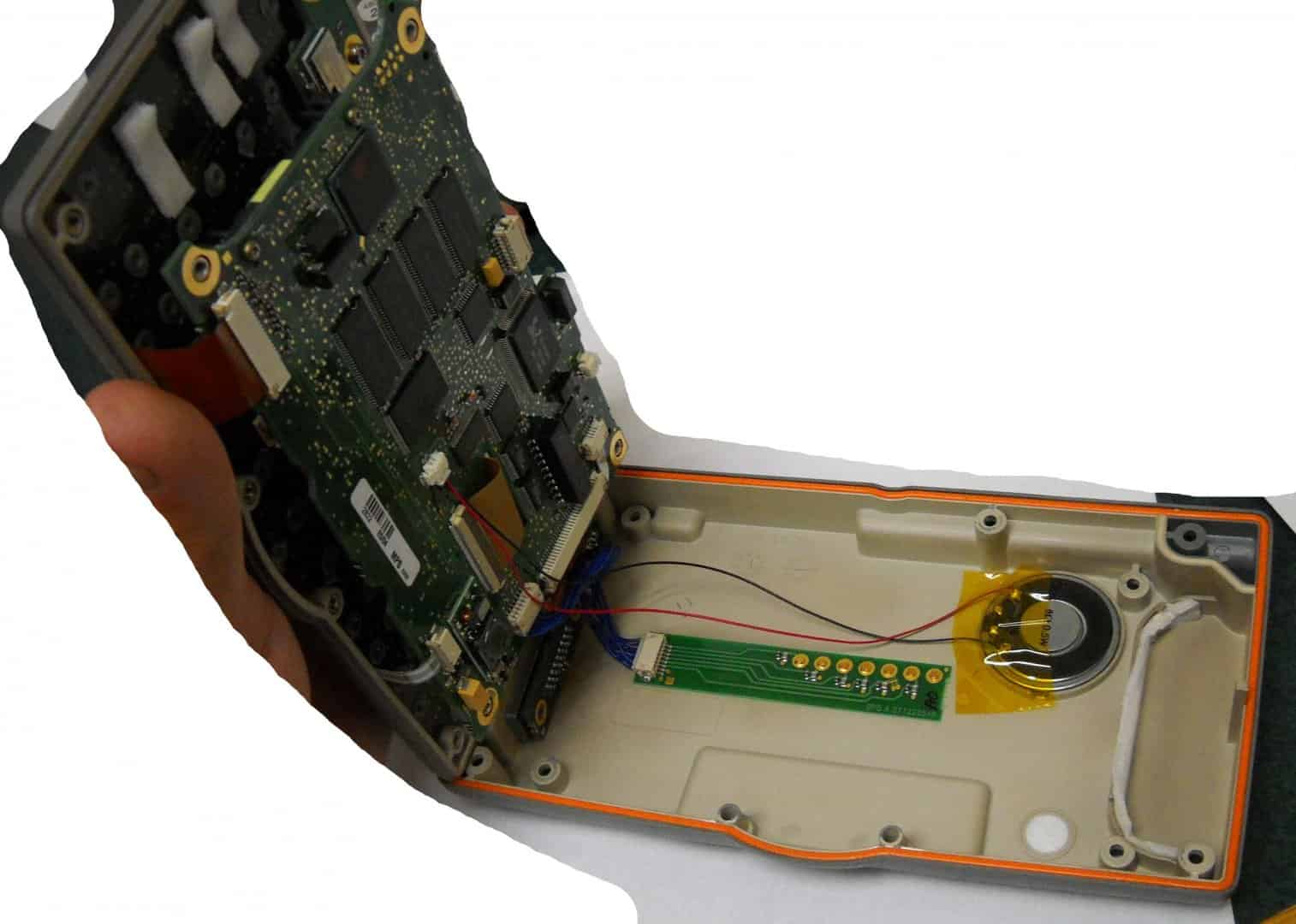

I also found it interesting that the "hard drive" is just a compact flash card.

imaudigger, post: 430812, member: 7286 wrote: I'll let you know next week when I plug the new batteries in. I'm pretty confident that it will fire up just fine (considering the battery has gone completely dead numerous time before).

I also found it interesting that the "hard drive" is just a compact flash card.

what instrument is this for again?

Trimble 5603

ACU Controller.

Are you saying you have replaced these batteries before? That's one nasty looking circuit board! Looks like it was stored outside in an old coffee can!

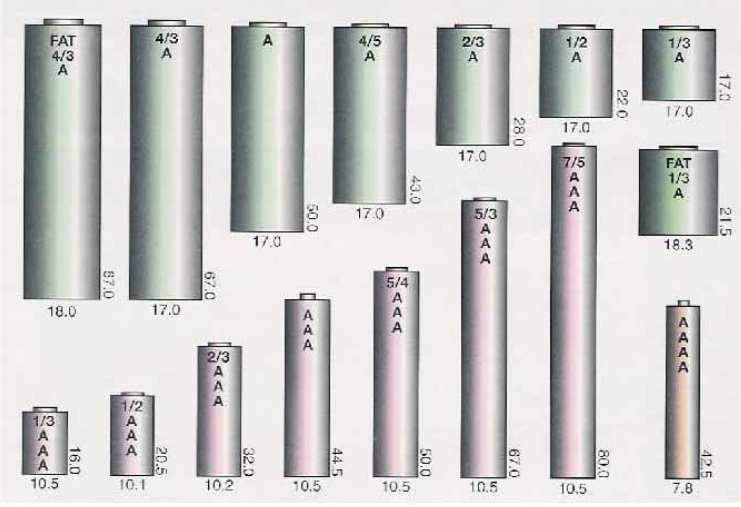

So ya - those are similar cells to what they will be using...The Trimble OEM batteries are AAAL (Long), I will use standard length AAA batteries and insert some foam to take up the extra space.

I didn't take the entire board out...just the battery.

Yeah, that's an ACU that's been in water. I have a working one for a 5600 so I pulled this damaged one apart to see what was in it. My working one does need batteries replaced soon but as per everywhere else official Trimble in Australasia wont touch them. I found a battery re-celler in New Zealand who said no problem to re-cell. They quoted NZD60, which is probably USD40. But they wanted the old pack so that they could re-use the wires (makes sense) but then I got scared off by the no-power-wipe-program possible issue so didn't go through with it. My 5600 has bad tracker alignment (300mm off at 200m) so I will send it all with the ACU to USA to get serviced, sometime. The other issue is that the ACU has SC 10.8 on it, which as far as I can work out, is a dog - I have a full Geodimeter 650 with SurvCE, which isn't a dog.

I'm fairly sure there's another post around (maybe on this forum) that suggests you can use LiPo instead of NiMH for these ACU's.

So I just got off the phone with a tech. at the company that serviced the instrument. He said it is not a hard and fast rule about not replacing the battery. In other words, if they feel it's going to be more effort than it pays, it is easier to say the battery isn't available.

If the customer is willing to agree before hand to waive any liability from using non-OEM parts and potentially pay a little more for the effort to source a battery - money talks.

He also said that he is fairly confident that the ACU should not lose any firmware/software by removing the battery, so I'm feeling better...

-----------------------------------------

I don't have the old battery with me, but it looks like it measured about 2.65 inches, which converts to 67.3 mm.

It must be a 5/3 AAA size. So I start searching for 5/3 AAA (which I have never even heard of).

Datona Industries shows 5/3AAA-1000NM being the equivalent of the GP100AAALH which is the Trimble OEM battery.

http://dantona.com/industrialsearch?dm_battery_number=134767&voltage=141349

Battery Giant sells the HR-5/3AAAU, which appears to be an equivalent.

https://www.batterygiant.com/batteries/HR-5/3AAAU

Some battery companies offer the batteries with tabs spot welded on and that may make it easier to build a cell pack. Probably worth taking the time to research if your going to build it yourself.

An update, I finally got my replacement battery pack and finished putting things together.

Here is a picture showing what it looked like after I took all of the screws out of the back. I only opened the case as far as I needed to gently pry the power connection apart (using the tip of a exact-o-blade). There are no clips, it is a friction connection. The arrows point to the power plug and two points where the OEM pack contacted the case.

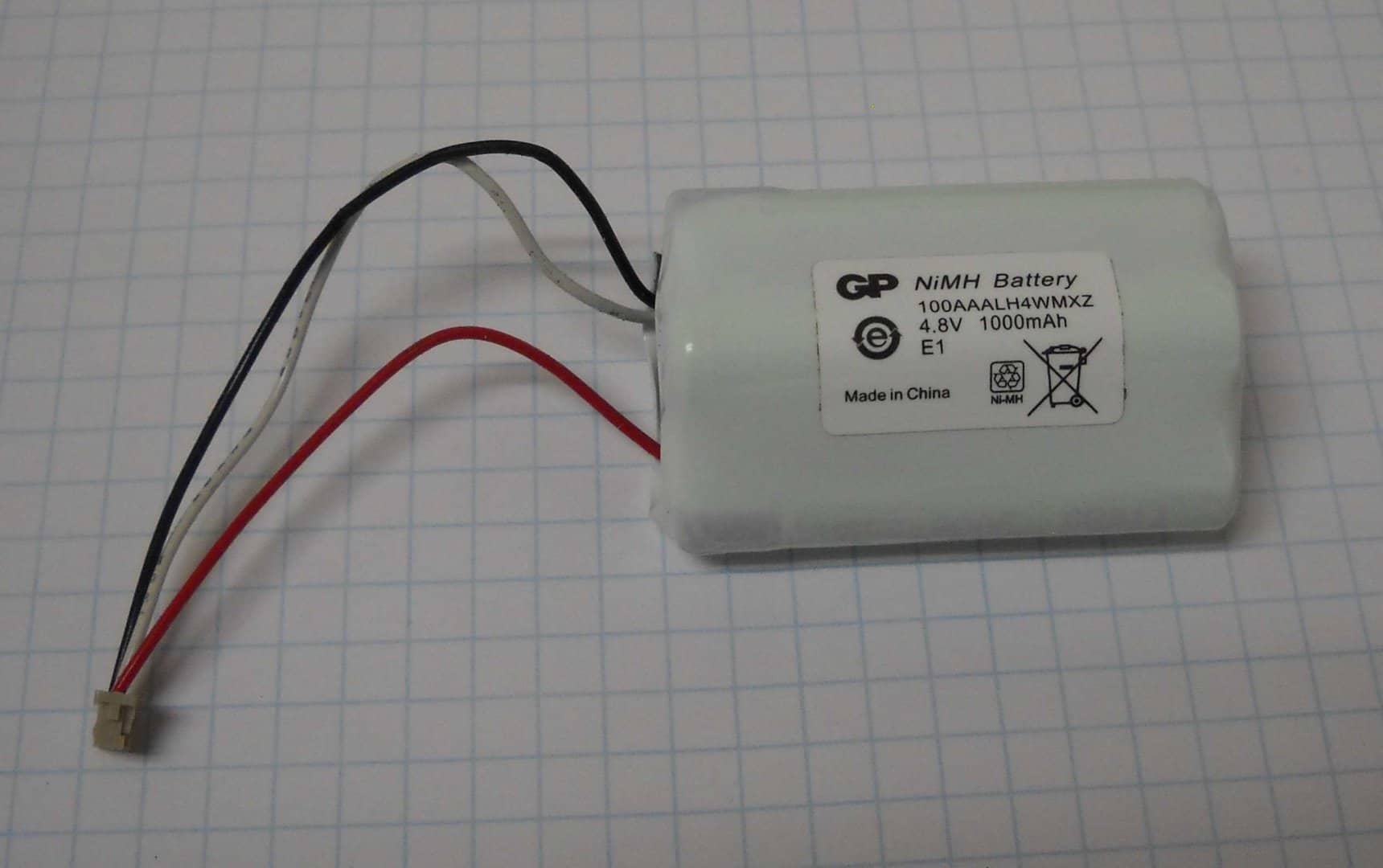

Here is the replacement battery pack. It was made using four 1.2 volt, 1000mAh 5/3AAA NMH cells, connected in series to achieve a nominal voltage of 4.8 volts. Batteries Plus took the sticker off the old OEM battery pack and transferred it to the new one. So the numbers really don't mean much other than to state the voltage and capacity. The OEM battery pack is packaged with the cells slightly staggered, while the replacement battery pack is packed flush at the ends.

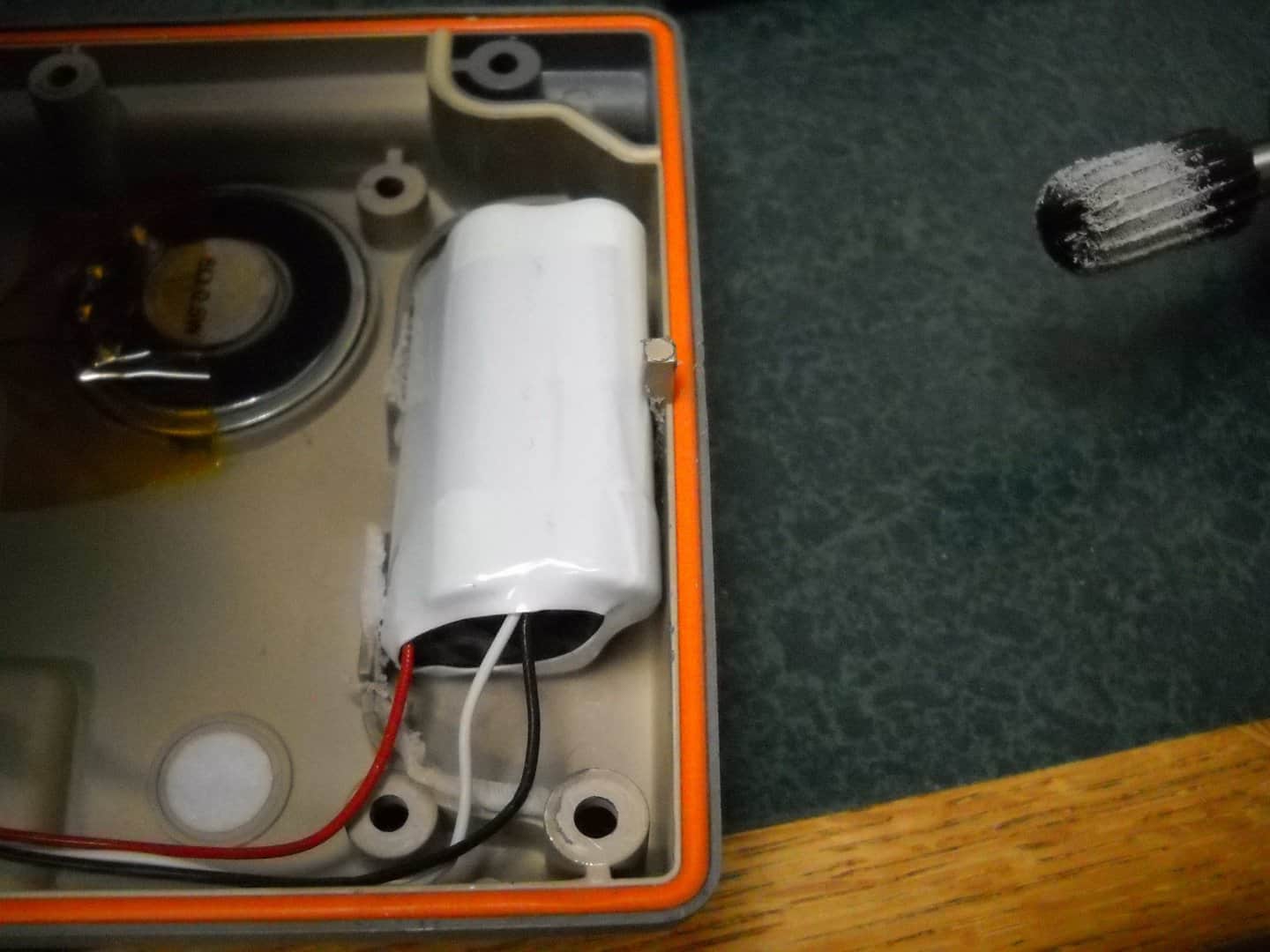

In order to gain access to the battery compartment, you can hinge the case apart without taking any other cabled off.

Presumably the OEM cells were staggered to make them a little smaller because the replacement battery pack was just a little too big to have the case close without putting undue pressure on the upper circuit board (pictured in the far left of the third photo). I had to remove some of the foam tape, as well as shave some of the internal case in order to get the battery pack to fit properly.

Here you can see how the battery pack is positioned in the case. To the right, you can see the rotary file that I used to contour the case, enabling the battery to rock over further towards the edge of the case. This reduces the height enough to get the case to close, while still exerting slight pressure on the battery. This pressure is enough that I did not have to use any foam spacers to keep the battery from sliding around.

Be careful that you remove enough material from the case, otherwise the battery will bow the edge of the case when you tighten the case screws. This would probably compromise the water seal. I think this is what the post is there to prevent. However it has been weakened from shaving the case.

When I first opened this case, I noticed that one of the battery wires was pinched in-between the case seal. Patience is required to get things to line up. I used the back side of an exact-o-knife to tuck the wires into the case before closing the case completely.

Did it power up?? Yup. Under Control Panel - Settings - Power management, I was able to see it was charging and had good voltage. I switched it to run on internal battery, which it did fine. Looks good.

Total cost = $35 ($25 for battery, $10 for rotary file bit)

As a side note, it is possible that the circuit boards could touch each other while all the screws are out if you are not careful.

I would consider allowing the battery to completely drain before taking it apart. This could be done by enabling the device to run on the internal battery.

Also being very careful about jostling the circuit boards after you plug the new battery in. It's entirely possible that the service guys leave the middle circuit board screwed to the case and unplug several ribbon cables to gain access to the battery.

Either way, the level of difficulty is pretty low for someone with attention to detail.