Stationary baler. You can move it to a hay stack, then feed the hay in with pitchforks. Slip in the boards to separate one bale from another. Hand tie the wires. Drag the bales away by hand to get them out of the way until a sled or wagon is available to stack them on for transport to the barn. Waaaaaaay before my day.

Holy Cow, post: 394125, member: 50 wrote: Stationary baler. You can move it to a hay stack, then feed the hay in with pitchforks. Slip in the boards to separate one bale from another. Hand tie the wires. Drag the bales away by hand to get them out of the way until a sled or wagon is available to stack them on for transport to the barn. Waaaaaaay before my day.

It was bad enough "throwing" those bales up into a wagon, much less handling them twice. Our balers used twine instead of wire, much easier on the hands. It makes my back (and knees) hurt just to think about it. Thank the Lord (and John Deere etc.) for all the improvements in farming equipment today.

Andy

I spent a morning bucking hay bales once many years ago, and concluded that it's a job better suited to someone who weighs more than 130 lbs.

https://en.wikipedia.org/wiki/Baler

You need to thank Virgil Haverdink and Professor Wesley F. Buchele at Iowa State. Wes was a good ol' southeast Kansas boy who understood how much work was involved in handling small bales.

http://www.amestrib.com/news/former-isu-professor-speaks-life-improving-farming

I shot pool with Wes in the basement of his home in Ames in September 1977.

[USER=10]@Jim Frame[/USER]

By the time I was six I was dragging bales across the hay mow floor to the big boys to stack. Put the hay hook in my leg for the first time about that same year. Started throwing them seriously shortly after that. We raised so much hay we always had far more than we could use so we sold and delivered hay all winter to other stockmen. That meant I touched most of those bales four times. Once on the trailer behind the baler, once into the barn/shed, once out of the barn/shed and once unloading at the buyer's barn/shed. It was the same number of touches for feeding them to our own cattle, so it was just normal. Like anything else, there is a "knack" to handling them with the least amount of effort involved. During my high school years there were numerous teams of three each doing custom hay hauling for local farmers. They would haul 1000 or more on a standard day from the field and stack in the barn/shed/boxcar/whatever. When the weather was threatening they might handle up to almost 2000 bales in a single day if everything went perfectly. That is a tremendous amount of work. On rare occasions I was able to break away from my own farming duties and spend a day or two working on one of those crews. Most earned three to four cents per bale hauled. Do you have any idea how many cases of beer one day's work would buy in those days? Far more than a wise man would consume in a day, especially if he wanted to work again the next day.

Have a couple of daughters who became experts at handling hay and one that got quite a bit of experience. The middle one has a hole in the top of her head (actually a tiny dimple) from a hay hook missed swing.

In reference to Nate's photos:

I emailed the pics to a friend that collects and restores old reciprocating engines along with Nate's assessment of the "1 cylinder engine on it". I thought he would be interested as he has several old "hit and miss" engines from antique farm equipment.

Interestingly he said he has seen several similar balers, but that one threw him. He can't ID the mfg. But one observation he made was that it appears to be driven by an external (tractor) motor from the large flywheel on the side. This left him wondering what it was that Nate saw that looked like a 1 cyl. engine & water tank. His interests are mainly in the power plants of old farm equipment and not the equipment itself. Anybody have any guesses as to the manufacturer?

I believe some came with both power options available, but I don't know that I ever saw one of those.

A demonstration. The large tamper on top shoves the loose hay into the bale chamber. Then the powerful plunger slides horizontally down the compaction chute to increase the bale density. The resistance to movement down the remainder of the chute can be adjusted to make the bale more or less dense. Note the wooden blocks that separate each bale from the next. The wires were fed through at the block. Nearly all were hand tied. The wire knotter came along later.

That predates me. Dad had worked with those. It was a major job to transport the baler around from farm to farm and to walk an old iron wheeled tractor that far. Most farm areas had a community baler and tractor to rent.

Dad bailed short bales for the public from the early 50s till round bales took over.

He started out with a MasseFergason stationary baler that ran off a belt hooked to Alis Chalmers WD bailing peanut vines and maise and vetch. Afterwards he moved on to one with its own motor.

The half ton truck could not pull it down the road, too tongue heavy.

With the arrival of coastal Bermuda grass thanks to the Farm Act that paid subsidies to grow it, when I turned 12 a modern square baler and hay rake and something called a mower conditioner was sitting in our pasture.

Spent my teen years in the hayfields from spriggin, fertilizing, raking and hauling. Dad did the cutting and bailing.

Developed thick skin and muscles.

Town folk thought I was some kind of hippie with bandanna over my head or face or just around my neck.

When the coach at school told me to start lifting weights told him he was crazy cause I was already lifting hundreds of bales of hay most every day.

With the onset of round balers becoming popular dad gradually got out of it all because the equipment was too expensive to keep going without it being a daily business.

It's a single cyl. because that is what comes from the distributor in pic 2. The thing on top is the water chamber. The fly wheel in pic one has a handle, to crank it. The baling wire is in pic 2, sitting on top of the tire.

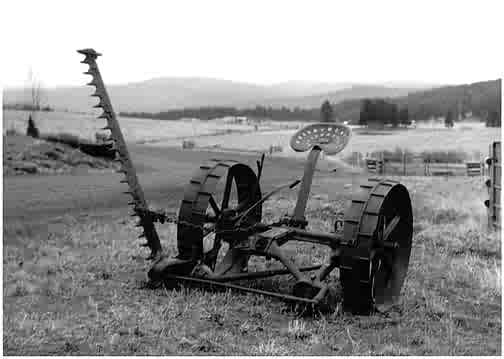

These are called by a couple different names- "Hay press" or "Stationary hay press".- the term "Baler" came later when they could automatically "bale" and tie/ wire the hay together without human assistance. This type would have been used while stationary in a field- hay would have already in a pile, or brought to the press on wagons, then pitched from the wagon into the middle section. The press would alternate between mechanically pushing the hay 1st downward into the chute area, then pushing it horizontally backward down the chute, - at a certain point a straight piece of wire would be inserted between the hay in the chute and wrapped around the sides of the bale to be manually tied. (see video below for a good example of how this worked)

Timeline for these is from early 1860's to ~1940's. Although this one may have had a gas-powered engine installed, most of these originally would have been powered by a belt run from a steam-powered traction engine (belt would run to the large spoked-wheel on the right side- in 2nd picture)- later gas-powered tractors had belt-pulleys to run these types of machines- My grandfather's circa 1950's John Deere Model 50 and Model 70 both had belt-drives running off the PTO. Many of the same companies that made steam-powered traction engines would have also carried these in their line of implements (Case, Rumley, Advance, Nolt-New Holland, and later the main implement manufacturers). A well known manufacturer named "Sandwich Manufacturing Co: of the town of Sandwich, Illinois started making these in 1861-

see: http://wellssouth.com/?p=98

more information on hay presses:

http://www.farmcollector.com/implements/hay-press-zmhz12fzbea

video of one in action:

[MEDIA=youtube]Qhz195aAxdo[/MEDIA]

Thanks Nathaniel!!! That was incredible. It's the kind of work I'd do.

We forget how much work was done, to keep this nation fed.

Thanks!

N

The object in the foreground of the 1st picture in the last set appears to be part of a cultivator, but hard to tell exactly due to the sticks and leaves covering it up.

1st pic, of the last group, looks like an old paddle wheel, off a Mississippi River Boat.

The first pic is a corn stalk chopper, I have one in much better condition, if no one has stolen it.

I wound up with all of the family's ancient farm equipment and people have been helping themselves to it for years.

It is all at the old home place about 95mi from where I live and hard to keep an eye on.

One of the many reasons I don't live there.

I agree on the stalk chopper. That was my initial thought before going in search of a similar photo. This is what the view from the rear should look like. These were used to chop up corn and milo stalks into smaller pieces to facilitate rotting and easier tillage prior to the next crop.

The second photo is very possibly an early fertilizer spreader. It could be a seeder but the almost complete rotting away of most of the material bin suggests evil, nasty fertilizer dust as the culprit.

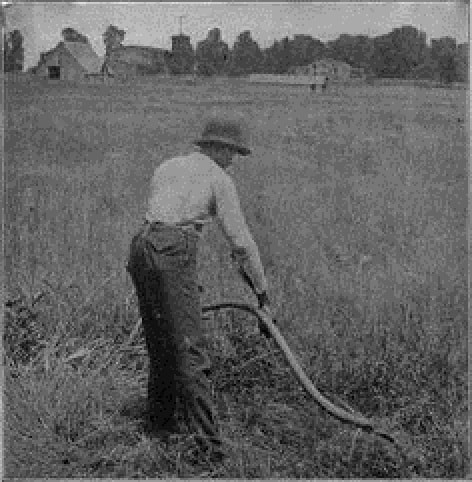

About 50 years ago my dad purchased a quarter-quarter adjacent to a quarter section we already owned. Along the east side there was a nice board gate in the fence separating our original tract from the new one. That made some sense to me as it was fairly close to the barnyard on the new place and adjacent to a nice pasture on the old place. I could imagine the former neighbor possibly having rented our pasture at some time in the past. But, along the west side of the new place there was a rickety old wire gate that separated pasture on the new place from pasture on the adjoiner's place. It also appeared to be in a somewhat odd location for moving livestock from one place to the other. When I asked my dad why the old wire gate would be there he went into a long winded dissertation on how farming worked long before I was born. He was talking about steam engines and steel wheeled tractors and steel wheeled implements of all kinds and disc harrows that you had to drag from place to place because they had no wheels or lifting mechanisms. Nearly everyone had gates like these in their fences to accommodate travel between farms by taking short cuts across the neighbor's lands rather than going down the county roads. That was also a time when many neighbors got together to share work for one guy before moving to the next and then the next performing major farm jobs. For example, in the days of the stationary baler or press, hay harvest was a major effort requiring a crew of men, boys, equipment and horses and mules. Mowing hay with a sickle mower being pulled by a horse or mule to get a swath of maybe four feet in width required several days to cut a large field or half a day with several mowers and horses/mules doing the job. Then the old dump rakes were used to gather the loose hay, when dry, into clumps to be pitched onto wagons to be taken to wherever the baler/press was positioned. It took several men to keep the baling process going efficiently from tossing it into the baler, to inserting and tying the wires, to moving the freshly made bales to the sled/wagon for transport, to stacking the bales in the barn/shed. This was not the kind of work that only one or two workers tried to do all by themselves if there was any other choice available.

Holy Cow, post: 394260, member: 50 wrote: ...Mowing hay with a sickle mower being pulled by a horse or mule to get a swath of maybe four feet in width required several days to cut a large field or half a day with several mowers and horses/mules doing the job..... This was not the kind of work that only one or two workers tried to do all by themselves if there was any other choice available.

A mule drawn sickle mower might have been frustratingly slow, but in my mind it beat the alternative...

Thank God Momma Cash married a city boy..;)

Trust me, I'll not take your scythe on the issue. BTW, I actually own a scythe like the one shown. Except for a few experimental whacks at some tall grass, it has remained safely stored in the garage for at least 24 years.

We had a few items of two-row, formerly horse-drawn implements around when I was 10 and under. They had been converted to be used with a tractor. A corn planter of that type was used a bit for planting sweet corn in the extension to our garden. I did get to ride around on the cast iron seat a time or two. Today that would be considered child endangerment. I thought it was great fun.